Regular maintenance of fire safety equipment, including fire hose reels and landing valves, is crucial. Neglecting maintenance can lead to severe consequences, such as equipment failure during emergencies. Key areas to focus on include the functionality of the Fire Hydrant Landing Valve, the condition of the 3 Way Landing Valve, the proper operation of the Flanged Hydrant Landing Valve, and ensuring that the Thread Type Landing Valve is in optimal working order.

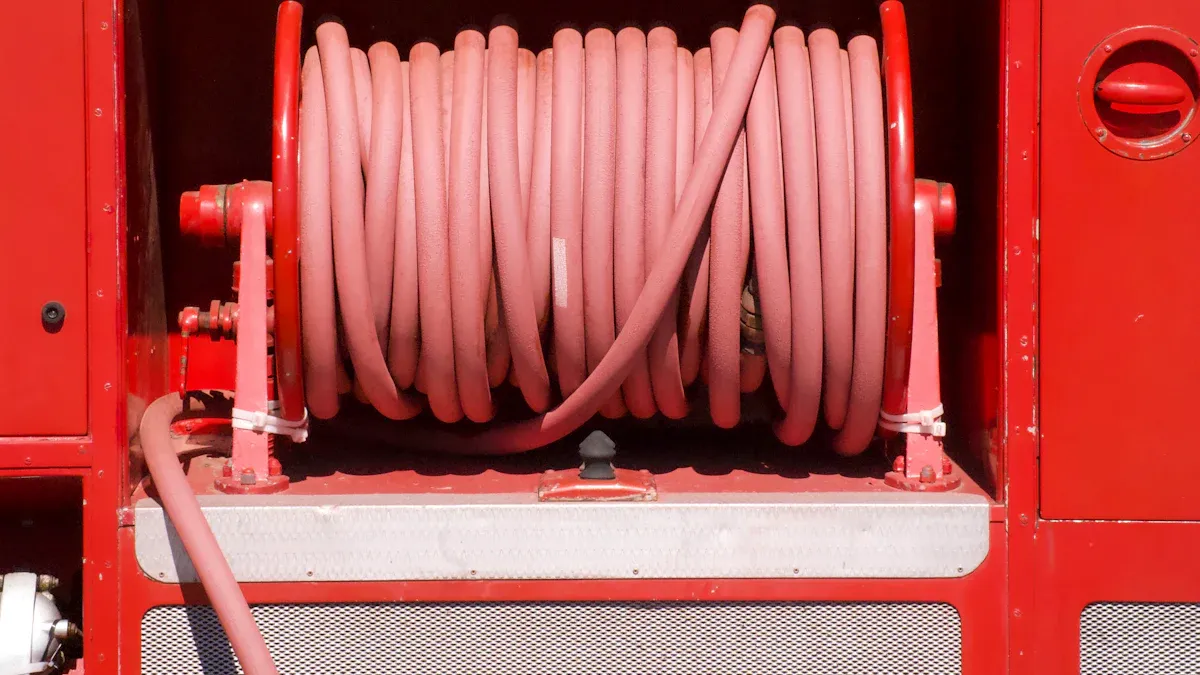

Proper Usage of Fire Hose Reels

Using fire hose reels correctly is essential for effective fire response. Proper usage ensures that individuals can quickly and safely extinguish fires when necessary. Here are the recommended procedures for operating a fire hose reel according to fire safety authorities:

- Locate the fire hose reel and make sure it is accessible.

- Unlock the hose reel cabinet using the provided key or opening mechanism.

- Pull out the hose from the reel and ensure it is fully extended.

- Open the valve to allow water to flow through the hose.

- Hold the nozzle and direct the water towards the base of the fire, sweeping from side to side.

- Continue spraying water until the fire is fully extinguished.

- After use, turn off the valve and carefully rewind the hose back onto the reel.

- Return the nozzle to its proper place and close the hose reel cabinet.

When using a fire hose reel, safety should always come first. Consider the following precautions:

- Wear appropriate protective clothing and safety gear, such as gloves and goggles.

- Position yourself at a safe distance from the fire to avoid heat and smoke.

- Do not aim the water stream at electrical equipment or live electrical sources.

- Avoid kinking or twisting the hose, as it may disrupt water flow.

- If the fire becomes uncontrollable or starts to spread, evacuate the area and call the fire department.

Improper usage of fire hose reels can significantly impact their effectiveness during a fire emergency. Untrained individuals may misuse the equipment, potentially worsening the fire or putting themselves at risk. For example, water can exacerbate certain types of fires, such as oil fires, leading to more dangerous situations. Additionally, staying too long to fight a fire can expose individuals to toxic smoke and fumes, increasing the risk to their safety.

To minimize user errors, it is crucial to follow best practices. Common mistakes include:

- Not placing the fire hose in a strategically positioned place.

- Not replacing or controlling the supply of the fire retardant after use.

- Inspecting the fire hose reel infrequently.

- Not investing in a high-quality fire hose cover.

- Not conforming to industry standards.

Training programs can enhance the knowledge and skills required for proper fire hose reel usage. Here are some available courses:

| Course Name | Duration | Cost | Certification Outcome |

|---|---|---|---|

| IFEDA Fire Hose Reel Course | 1 day | From £335.00 + VAT | CPD Accreditation |

| Routine Service of Fire Hose Reels | N/A | Standard Enrolment $265 | Statement of Attainment for CPPFES2010 |

These courses cover essential topics such as relevant legislation, industry standards, and safety practices. Investing in training ensures that individuals are well-prepared to handle fire emergencies effectively.

By adhering to these guidelines and participating in training, individuals can maximize the effectiveness of fire hose reels and contribute to a safer environment.

Cleaning Your Fire Hose Reel

Regular cleaning of fire hose reels is essential for maintaining their functionality and longevity. Proper cleaning prevents dirt and debris from accumulating, which can hinder performance during emergencies. Follow these steps to clean your fire hose reel effectively:

- Prepare a solution of warm water and mild detergent.

- Use a long brush with soft to medium bristles to scrub the hose gently.

- Rinse the hose thoroughly to remove all detergent from both sides of the hose jacket.

- Ensure the hose is completely dry before storage. Avoid placing it on hot pavement or exposing it to direct sunlight.

To maintain optimal performance, fire hose reels should undergo regular inspections. The following table outlines the recommended cleaning and inspection frequency:

| Inspection Type | Frequency |

|---|---|

| Visual Inspection | Monthly |

| Comprehensive Inspection | Quarterly |

| Service Testing | Annually |

Regular testing is crucial for reliability. It helps identify potential issues early and ensures optimal performance during emergencies. By adhering to these cleaning practices, individuals can enhance the effectiveness of fire hose reels and contribute to a safer environment. Remember, a clean fire hose reel is a reliable fire hose reel

Inspection of Fire Hose Reels

Regular inspection of fire hose reels is vital for ensuring operational readiness. A thorough inspection helps identify potential issues before they become critical. Here are the key steps involved in inspecting a fire hose reel:

- Record-Keeping: Document inspection dates, personnel involved, and results.

- Unroll the Hose: Fully extend the hose and check for integrity along its length.

- Water Test: Conduct a pressure test to ensure no leaks exist and that water flows unobstructed.

- Inspect Fittings and Valves: Check all fittings and valves for functionality through visual and practical tests.

- Compliance: Ensure all inspections meet local laws and regulations.

During inspections, personnel should also focus on specific areas:

- Inspect the hose and nozzle for any damage.

- Test the nozzle to ensure smooth operation.

- Run water through the hose to check for flow rate and blockages.

- Periodically flush the hose to maintain compliance.

To facilitate effective inspections, consider using the following checklist:

| Inspection Type | Frequency | Description |

|---|---|---|

| Visual Inspections | Monthly | Check for damage, corrosion, and ensure proper winding and secure connections. |

| Flow Tests | Annually | Run water through the hose to ensure adequate supply and check for leaks or kinks. |

| Pressure Tests | Every five years | Verify the hose can withstand 1.5 times the maximum working pressure to ensure optimal performance. |

By adhering to these inspection practices, individuals can enhance the reliability of fire hose reels. Regular inspections not only ensure compliance but also contribute to overall fire safety.

Storage Best Practices

Proper storage of fire hose reels is essential for maintaining their integrity and ensuring they function effectively during emergencies. Follow these best practices to enhance the longevity of your fire hoses:

- Clean and Dry: Always clean and dry hoses before storage. This prevents contamination and reduces the risk of mold or mildew.

- Ventilated Cabinets: Use lockable, ventilated cabinets to store hoses. This setup prevents moisture buildup, which can weaken the material.

- Temperature Control: Maintain storage temperatures between 10°C and 24°C (50°F and 75°F). Avoid high temperatures that can cause rubber to dry out and crack.

- Avoid Direct Sunlight: Store hoses away from direct sunlight, ozone, and chemicals. Exposure can degrade rubber, leading to stiffness and brittleness.

- Proper Coiling: Coil hoses in large, even loops to avoid kinks and tangles. Kinking can damage the hoses and reduce their effectiveness.

- Regular Inspections: Regularly inspect stored hoses for signs of wear or damage. Replace any hoses that show cracks, bulges, or leaks.

Tip: Change the position of folded hoses every three months to prevent permanent creases and maintain their shape.

By adhering to these storage practices, individuals can significantly enhance the reliability and lifespan of fire hose reels. Proper storage not only protects the equipment but also ensures readiness when it matters most.

Maintenance Tips for Landing Valves

Maintaining landing valves is crucial for ensuring their functionality and reliability during emergencies. Regular maintenance tasks help prevent issues that could compromise fire safety. Here are essential maintenance tasks for landing valves:

| Maintenance Task | Description |

|---|---|

| Checking for leaks | Inspect the valve for any signs of leakage. |

| Ensuring valve operation | Verify that the valve mechanism operates smoothly. |

| Verifying hose connections | Check that the hose connections are secure. |

| Scheduled inspections | Conduct inspections quarterly or semi-annually. |

Regular inspections help identify potential problems early. Common issues encountered during maintenance checks include:

| Issue Type | Description |

|---|---|

| Stuck Valves | Caused by corrosion, debris accumulation, and inadequate lubrication. |

| Corroded Valves | Weakens components leading to leaks, sticking, and potential failure. |

| Overheating | Results in improper sealing due to expansion of the valve body from excessive temperatures. |

To address specific problems, consider the following:

- Valve won’t close: Check for debris in the line or travel issues.

- Leaking valve: Inspect for installation issues, packing leaks, or damage to gaskets.

Common causes of leakage include unreliable seals, contaminants, and improper installation. Leakage can be categorized into two types: seat leaks, where fluid passes through the seal, and shell leaks, where fluid escapes into the atmosphere.

Cleaning and lubrication are vital for maintaining landing valves. Before applying any lubricant, clean the valve and its surrounding areas to remove dirt. Regular cleaning, ideally at least once a year, extends the life of the entire system. Inspecting the valves for leaks is crucial; repairs should be made before lubrication to ensure optimal performance.

Here are recommended cleaning procedures:

| Cleaning Procedure | Description |

|---|---|

| Anti-corrosion Coatings | Apply coatings to prevent corrosion and rust on valve components. |

| Regular Inspections | Conduct inspections to identify early signs of rust and corrosion. |

| Wire Brushes/Sandblasting | Use these methods to remove existing rust from the valves. |

| Rust Inhibitor Application | Apply inhibitors or primers after cleaning to protect against future damage. |

| Replacement of Corroded Parts | Replace any severely corroded components to maintain functionality. |

For lubrication, consider using Fuchs FM Grease 387 for hydrants. Avoid food-grade grease containing acetate, as it may not provide adequate protection.

According to fire safety regulations, landing valves should be serviced regularly. Here are the recommended inspection frequencies:

- Inspect fire landing valves at least once a month.

- Monthly inspections help identify potential issues and ensure reliable operation.

- Conduct a comprehensive inspection at least once a year, including testing pressure and flow rates.

By adhering to these maintenance tips, individuals can ensure that landing valves remain functional and reliable, contributing to overall fire safety.

Compliance with Standards

Compliance with fire safety standards is essential for maintaining the functionality of fire hose reels and landing valves. Key standards governing these systems include:

- NFPA 24: This standard outlines installation requirements for private fire service mains and components, including fire landing valves.

- NFPA 25: This standard provides guidelines for the inspection, testing, and maintenance of water-based fire protection systems, ensuring operational readiness.

- Documentation: Accurate records of installations and maintenance support compliance and accountability.

Installers must also comply with local regulations. Many jurisdictions require permits for fire protection system installations to ensure adherence to safety standards. Engaging with local fire marshals or building inspectors helps clarify compliance requirements and avoid mistakes.

Non-compliance can lead to severe consequences. Regulatory fines may range from hundreds to tens of thousands of dollars per violation. Repeat offenders face multiplied fines and potential facility closure. Additionally, businesses may experience operational downtime due to Stop Work Orders or delayed occupancy permits, resulting in lost revenue.

Insurance fallout is another risk; non-compliance may lead to denied claims or increased premiums. Legal liability can arise from lawsuits for wrongful death or personal injury if violations are ignored. Furthermore, failing inspections can damage a business’s reputation, leading to a loss of customers and partners.

By adhering to established standards, businesses can ensure the reliability of their fire safety systems and protect their operations.

Fire Hydrant Landing Valve Maintenance

Maintaining the Fire Hydrant Landing Valve is essential for ensuring its reliability during emergencies. Regular maintenance helps prevent failures that could compromise fire safety. Here are the recommended maintenance steps:

- Conduct a visual inspection of the hydrant for any loose or missing parts.

- Ensure the top valve seat is fully closed, then check for water in the barrel by removing a nozzle cap.

- Open the hydrant fully and then close it slowly to prevent water hammer.

- Drain the hydrant and check for thread damage, cleaning and lubricating as necessary.

- Ensure chains are free hanging and adjust if needed.

- Lubricate the hydrant through the top valve seat using manufacturer-recommended lubricant.

Additionally, exercising the hydrant ensures it operates correctly. Regular lubrication prevents corrosion, while flushing removes foreign substances. Inspecting for standing water is crucial to prevent freezing, especially in colder climates.

Common failures reported during emergencies include stress corrosion cracking of stainless steel components, particularly in tropical environments. Water surge or hammer can exacerbate these issues, leading to significant operational challenges.

Fire hydrants should undergo inspections at least once a year, as local regulations and manufacturer recommendations may dictate more frequent checks. By adhering to these maintenance practices, individuals can ensure that the Fire Hydrant Landing Valve remains functional and ready for use when needed.

Regular maintenance of fire hose reels and landing valves is vital for ensuring reliable fire protection. Establishing a maintenance schedule offers numerous benefits, including:

- Ensuring readiness for emergencies.

- Complying with safety standards.

- Reducing the risk of equipment failure.

Building managers should prioritize these practices to enhance safety and compliance. By doing so, they protect lives and property effectively.

FAQ

What is the recommended frequency for inspecting fire hose reels?

Inspect fire hose reels monthly for visual checks and conduct comprehensive inspections quarterly.

How can I prevent corrosion on landing valves?

Apply anti-corrosion coatings and lubricate regularly to protect landing valves from rust and deterioration.

What should I do if I find a leak in a landing valve?

Immediately inspect the valve for debris or damage. Repair or replace any faulty components to ensure functionality.

Post time: Sep-18-2025