Proper installation of fire landing valves and fire hose reels plays a critical role in ensuring safety and compliance with regulations. Fire landing valves are essential components in landing valve fire fighting systems, as they directly impact firefighting effectiveness. When installed correctly, these fire hydrant landing valves and fire hose reels provide firefighters with reliable access to the water supply, enhancing their ability to combat fires efficiently.

Compliance with Codes and Standards

NFPA Guidelines

The National Fire Protection Association (NFPA) establishes critical guidelines for the installation of fire landing valves and hose reels. These guidelines ensure that fire protection systems operate effectively during emergencies. Adhering to NFPA standards helps organizations maintain safety and compliance.

- Installation Standards: NFPA 24 outlines the requirements for the installation of private fire service mains and their components, including fire landing valves. Installers must follow these specifications to ensure proper functionality.

- Testing and Maintenance: NFPA 25 provides guidelines for the inspection, testing, and maintenance of water-based fire protection systems. Regular testing of fire landing valves ensures they remain operational when needed.

- Documentation: NFPA guidelines emphasize the importance of maintaining accurate records of installations, inspections, and maintenance activities. This documentation supports compliance and enhances accountability.

Local Building Codes

In addition to NFPA guidelines, local building codes play a significant role in the installation of fire landing valves and hose reels. These codes vary by jurisdiction but generally align with national standards to ensure safety.

- Compliance with Local Regulations: Installers must familiarize themselves with local codes that govern fire safety. These regulations often include specific requirements for the placement and accessibility of fire landing valves.

- Permitting Process: Many jurisdictions require permits for the installation of fire protection systems. This process ensures that installations meet local safety standards and undergo necessary inspections.

- Collaboration with Local Authorities: Engaging with local fire marshals or building inspectors can provide valuable insights into compliance requirements. This collaboration helps prevent costly mistakes and ensures that installations meet all necessary standards.

By adhering to both NFPA guidelines and local building codes, organizations can enhance the effectiveness of their fire protection systems. Proper installation of fire landing valves not only meets regulatory requirements but also significantly improves safety during emergencies.

Proper Spacing and Accessibility

Proper spacing and accessibility are crucial for the effective operation of fire landing valves and hose reels. These elements ensure that firefighters can quickly access the necessary equipment during emergencies.

Minimum Distance Requirements

Installers must adhere to minimum distance requirements when positioning fire landing valves and hose reels. These requirements help maintain safety and functionality.

- Clearances: Fire landing valves should have a minimum clearance of 36 inches around them. This space allows firefighters to operate the valves without obstruction.

- Proximity to Hazards: Installers must avoid placing fire landing valves near potential hazards, such as flammable materials or electrical equipment. Keeping a safe distance reduces the risk of accidents during firefighting operations.

- Accessibility for Equipment: Ensure that fire hose reels are installed within a reasonable distance from fire landing valves. This proximity allows for quick connection and deployment of hoses, enhancing firefighting efficiency.

Clear Pathways for Access

Creating clear pathways to fire landing valves and hose reels is essential for rapid response during emergencies.

- Unobstructed Access: Pathways leading to fire landing valves must remain free of obstacles. This includes furniture, landscaping, or any other items that could hinder access.

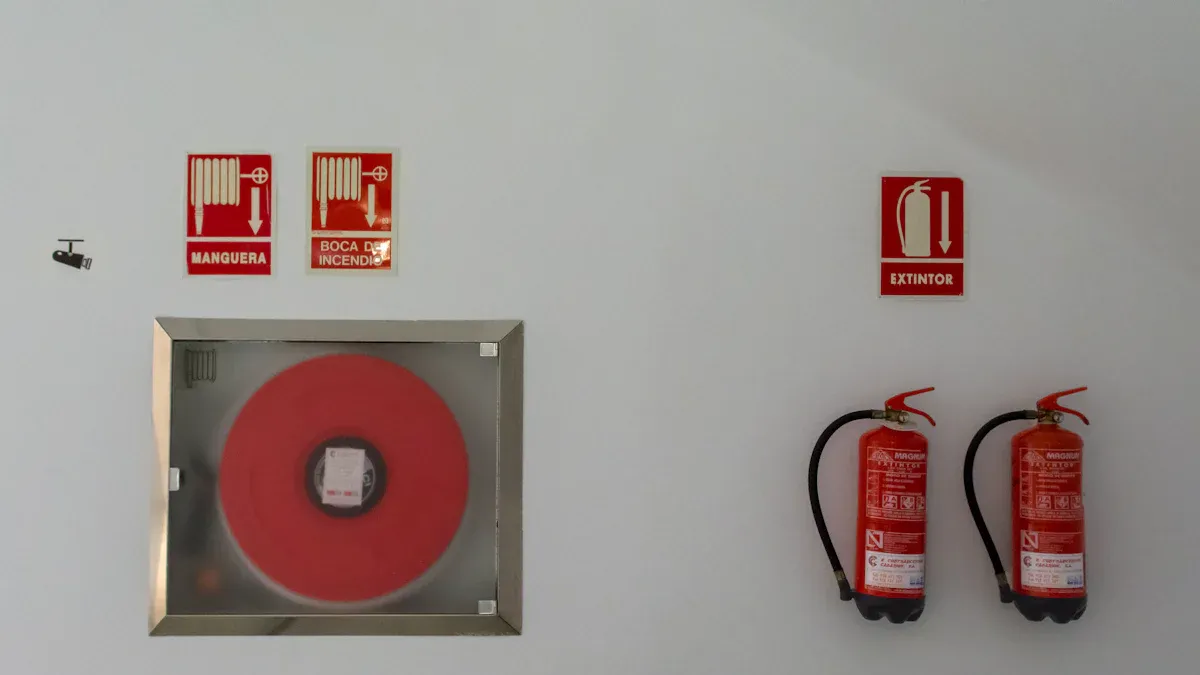

- Signage: Install clear signage to indicate the location of fire landing valves and hose reels. This signage should be visible from a distance and easy to read, guiding firefighters to the equipment quickly.

- Regular Maintenance: Conduct regular inspections to ensure that pathways remain clear. Any obstructions should be removed immediately to maintain accessibility.

By following these spacing and accessibility guidelines, organizations can significantly improve the effectiveness of their fire protection systems. Properly installed fire landing valves and hose reels, with adequate spacing and clear access, enhance the safety of both firefighters and building occupants.

Fire Landing Valves Connection Requirements

Proper connections are vital for the effective operation of fire landing valves. Understanding the types of connections and following pressure testing procedures ensures that these systems function correctly during emergencies.

Types of Connections

Fire landing valves can utilize various connection types, each designed for specific applications. Below is a table summarizing the most common connection types used in commercial and residential buildings:

| Connection Type | Description |

|---|---|

| Dry riser landing valve thread | Valves installed in dry riser systems, threaded and connected to the standpipe. |

| Groove to ISO 6182 | Grooved end connection for fire valves compliant with ISO 6182 standard. |

| Flange to BS EN 1092-2:1997 | Flanged end connections in accordance with British Standard EN 1092-2:1997. |

Selecting the appropriate connection type is crucial for ensuring compatibility with existing systems and maintaining safety standards.

Pressure Testing Procedures

Pressure testing is essential for verifying the integrity of fire landing valves. This process helps identify leaks and ensures that the valves can withstand operational pressures.

- Initial Testing: Conduct pressure tests after installation to confirm that all connections are secure.

- Regular Maintenance: Schedule periodic pressure tests to ensure ongoing reliability.

- Documentation: Maintain records of all pressure tests, including results and any necessary repairs.

By adhering to these connection requirements and pressure testing procedures, organizations can enhance the reliability of their fire landing valves. This diligence not only meets regulatory standards but also significantly improves safety during firefighting operations.

Signage and Marking

Visibility of Valves and Reels

Visibility plays a crucial role in the effectiveness of fire landing valves and hose reels. Firefighters must quickly locate these essential components during emergencies. To enhance visibility, consider the following practices:

- High-Contrast Colors: Use bright colors for valves and reels to ensure they stand out against their surroundings.

- Reflective Materials: Incorporate reflective materials in signage to improve visibility in low-light conditions.

- Strategic Placement: Position valves and reels in easily accessible locations. Avoid placing them behind obstacles or in poorly lit areas.

By implementing these strategies, organizations can significantly improve the chances of rapid access to firefighting equipment.

Instructional Signage

Instructional signage provides critical information about the operation of fire landing valves and hose reels. Clear and concise instructions help ensure that personnel can use the equipment effectively. Key elements of effective instructional signage include:

- Simple Language: Use straightforward language that is easy to understand. Avoid technical jargon that may confuse users.

- Visual Aids: Incorporate diagrams or images to illustrate the steps for operating the equipment. Visual aids can enhance comprehension.

- Placement: Position instructional signs near the equipment. This proximity allows users to reference the instructions quickly when needed.

Tip: Regularly review and update signage to reflect any changes in procedures or equipment. Keeping information current ensures that all personnel remain informed.

By prioritizing visibility and providing clear instructional signage, organizations can enhance the safety and effectiveness of their fire protection systems. Proper signage not only aids firefighters but also contributes to overall emergency preparedness.

Maintenance Requirements

Regular maintenance of fire landing valves and hose reels is essential for ensuring their reliability during emergencies. Establishing a systematic approach to inspections and repairs can significantly enhance the effectiveness of these critical fire protection systems.

Regular Inspection Schedules

Organizations should implement regular inspection schedules to maintain fire landing valves and hose reels. These inspections help identify potential issues before they escalate. Consider the following practices:

- Monthly Inspections: Conduct monthly checks to ensure that all components are functioning correctly. Look for signs of wear, corrosion, or leaks.

- Annual Comprehensive Inspections: Schedule a thorough inspection at least once a year. This inspection should include testing the pressure and flow rates of fire landing valves.

- Documentation: Maintain detailed records of all inspections. This documentation supports compliance with safety regulations and helps track maintenance history.

Repair and Replacement Protocols

When issues arise, prompt repairs or replacements are crucial. Establishing clear protocols can streamline this process:

- Immediate Reporting: Encourage personnel to report any malfunctioning equipment immediately. Quick action can prevent further damage or safety risks.

- Qualified Technicians: Only qualified technicians should perform repairs. This ensures that all work meets industry standards and maintains system integrity.

- Replacement Guidelines: Develop guidelines for replacing outdated or damaged equipment. Regularly assess the condition of fire landing valves and hose reels to determine when replacements are necessary.

By adhering to these maintenance requirements, organizations can ensure that their fire landing valves and hose reels remain operational and effective during emergencies.

Training for Personnel

Importance of Training

Training personnel in the proper use and maintenance of fire landing valves and hose reels is vital for safety and effectiveness. Well-trained staff can respond quickly and efficiently during emergencies. They understand how to operate equipment correctly, which minimizes the risk of accidents. Regular training sessions help reinforce knowledge and skills, ensuring that all personnel remain prepared.

Training also fosters a culture of safety within the organization. When employees recognize the importance of fire safety equipment, they are more likely to prioritize its maintenance and proper usage. This proactive approach can significantly reduce the likelihood of equipment failure during critical moments.

Training Programs and Resources

Organizations should implement comprehensive training programs that cover essential aspects of fire landing valves and hose reels. Effective training programs typically include:

- Regular maintenance and inspection: Personnel should learn the importance of conducting inspections at least once a year to ensure reliability and performance.

- Routine maintenance steps: Training should cover inspecting hoses for wear, checking valve operation, examining nozzles, verifying reel mechanism function, testing water flow, and ensuring visibility of signage.

- Common maintenance issues: Awareness of potential problems, such as hose deterioration, corroded components, nozzle blockages, and damaged mechanisms, is crucial for effective maintenance.

Utilizing available resources, such as online courses, workshops, and manufacturer training sessions, can enhance personnel knowledge. Organizations can also collaborate with local fire departments to provide hands-on training experiences. By investing in training, organizations ensure that their personnel are equipped to handle fire emergencies effectively.

In summary, effective installation practices for fire landing valves and hose reels include:

- Compliance with NFPA guidelines and local codes.

- Ensuring proper spacing and accessibility.

- Conducting regular inspections and maintenance.

Adhering to these practices significantly enhances safety and reduces fire-related losses. Organizations should regularly review and update their installation protocols to maintain compliance and effectiveness.

FAQ

What are fire landing valves?

Fire landing valves are essential components of fire protection systems. They provide firefighters with access to a water supply during emergencies.

How often should fire landing valves be inspected?

Organizations should inspect fire landing valves at least once a month. Regular inspections help identify potential issues and ensure reliable operation.

What training is necessary for personnel using fire hose reels?

Personnel should receive training on operating fire hose reels, conducting inspections, and performing routine maintenance. This training enhances safety and effectiveness during emergencies.

Post time: Sep-11-2025