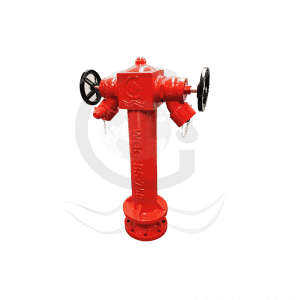

A wet type fire hydrant, such as the Two Way Fire Hydrant, provides instant water access for outdoor fire emergencies. Its double outlet fire hydrant design allows firefighters to connect hoses quickly. The two way pillar fire hydrant ensures reliable performance in public spaces, supporting fast and effective fire response.

Wet Type Fire Hydrant: Definition and Outdoor Operation

How Wet Type Fire Hydrants Work Outdoors

A wet type fire hydrant provides a constant supply of water above ground, making it ready for immediate use during emergencies. Firefighters can quickly connect hoses to the hydrant’s outlets, which remain filled with water at all times. Outdoor installation connects the hydrant to underground water supply pipes, ensuring a steady flow. This setup supports large-scale firefighting in open areas, such as shopping centers or campuses, where fast access to water is critical.

Tip: Placing hydrants near building water pump connectors helps firefighters reach water quickly during emergencies.

The hydrant’s design allows each outlet to operate independently. This means multiple hoses can be used at once, giving fire crews flexibility and speed. The hydrant’s outdoor location ensures it is easy to spot and access, which is vital for rapid response.

| Feature | Wet Barrel (Wet Type) Hydrant | Dry Barrel Hydrant |

|---|---|---|

| Valve Location | Above ground, at each outlet | Below frost line underground |

| Water Presence in Barrel | Water present above ground | Barrel normally dry |

| Operation | Each outlet can be turned on/off | Single stem operates all outlets |

| Climate Suitability | Warm areas, no freezing risk | Cold climates, prevents freezing |

| Freezing Risk | Susceptible to freezing | Drains water after use |

| Operational Flexibility | Individual outlet control | All outlets operate together |

Design Features for Outdoor Use

Manufacturers build wet type fire hydrants with heavy-duty materials like cast iron or ductile iron. These materials help the hydrant withstand outdoor conditions and high water pressure. The hydrant features removable nozzles, which allow firefighters to attach hoses quickly. Each outlet has its own valve, so teams can use more than one hose at a time.

Recent advancements include smart sensors for real-time monitoring, corrosion-resistant coatings, and GPS technology for easy location. These features improve durability, performance, and emergency response. The hydrant’s simple design makes it easy to operate and maintain, especially in warm climates where freezing is not a concern.

Key Benefits of Wet Type Fire Hydrant for Outdoor Fire Protection

Instant Water Availability

A wet type fire hydrant delivers water instantly during emergencies. Firefighters open the hydrant and water flows immediately because the barrel stays filled at all times. This design eliminates delays and supports rapid response. Hydrants like the Series 24 Wet Barrel meet AWWA C503 standards and hold UL and FM certifications, confirming their reliability for outdoor fire protection. Pressure testing at twice the rated working pressure ensures the hydrant remains ready for use. High-strength materials such as ductile iron and stainless steel prevent leaks and failures. O-ring seals and mechanically locked nozzles further guarantee water is always available.

- Water remains in the hydrant barrel, ready for immediate use.

- Hydrant construction meets strict safety and durability standards.

- Corrosion-resistant components support long-term reliability.

Fire crews rely on instant water access to control fires quickly and protect property.

Simple and Fast Operation

Wet type fire hydrants feature a straightforward design that makes operation easy and efficient. Each outlet has its own valve, allowing multiple hoses to connect and operate at the same time. Mechanical parts sit above ground, so firefighters can adjust and maintain the hydrant without difficulty. There is no need to wait for the hydrant to fill or build pressure. The hydrant stays ready for use in warm or temperate climates.

- Water is always present up to each outlet.

- Independent valves allow simultaneous hose connections.

- Above-ground parts simplify adjustments and maintenance.

Firefighters save valuable time during emergencies because wet type fire hydrants offer immediate water flow and easy access.

Reliable Performance in Warm Climates

Wet type fire hydrants perform reliably in outdoor settings where freezing temperatures do not occur. Their mechanical parts remain above ground, and water flows close to the surface. This design suits warm climates and ensures consistent operation. Industry experts recognize wet barrel hydrants as the standard for non-freezing environments. With proper maintenance, these hydrants can last over 100 years. Their simple mechanism supports durability and reduces the risk of failure.

Wet type fire hydrants provide dependable fire protection for malls, campuses, hospitals, and other public spaces in mild climates.

Low Maintenance Requirements

Wet type fire hydrants require minimal maintenance due to their accessible design and durable materials. Routine inspections help prevent damage from vehicle collisions or improper valve operation. Fire departments recommend regular checks for leaks, obstructions, and signs of wear. Hydrant markers improve visibility and reduce the risk of accidental damage. With all mechanical parts above ground, repairs and upkeep become straightforward. Proper training for personnel includes inspecting, testing, and maintaining hydrants to ensure reliable operation.

| Maintenance Task | Frequency | Benefit |

|---|---|---|

| Visual inspection | Monthly | Detects leaks and damage |

| Flow testing | Annually | Confirms water availability |

| Lubrication | As needed | Ensures smooth operation |

| Accessibility check | Quarterly | Prevents obstructions |

Regular maintenance extends the lifespan of wet type fire hydrants and keeps outdoor fire protection systems ready for emergencies.

Wet Type Fire Hydrant vs. Dry Type Fire Hydrant

Differences in Water Supply and Operation

Wet type fire hydrants and dry type fire hydrants use different water supply mechanisms. Wet type fire hydrants keep water stored above ground inside the hydrant body. This design allows firefighters to access water instantly during emergencies. Dry type fire hydrants store water underground. The main valve sits below the frost line, keeping the barrel dry until someone opens the hydrant. This prevents freezing in cold climates.

| Feature | Wet Barrel Hydrant | Dry Barrel Hydrant |

|---|---|---|

| Water Location | Water stored above ground inside hydrant | Water stored underground |

| Climate Suitability | Suitable for areas without freezing risk | Suitable for freezing-prone areas |

| Valve Location | No internal valve; water always present | Main valve below ground to prevent freezing |

| Installation Complexity | Simpler and cheaper to install | More complex and expensive to install |

| Maintenance | Easier to maintain | More difficult to maintain |

| Operational Readiness | Immediate water access | Barrel remains dry until valve is opened |

Wet type fire hydrants offer immediate water flow and individual outlet control. Dry type hydrants require more complex installation and regular inspection.

Suitability for Outdoor Environments

The choice between hydrant types depends on the outdoor environment. Wet type fire hydrants work best in warm climates where freezing does not occur. Their above-ground parts make maintenance easy. Dry type fire hydrants fit cold climates. Their design prevents water from freezing inside the hydrant. Other factors include water supply pressure, fire risk level, and local codes. Facility layout also matters. Hydrants should be easy to reach and provide good coverage.

Tip: Always check local regulations before choosing a hydrant type for outdoor use.

Choosing the Right Hydrant for Your Property

Property owners should consider climate, installation cost, and maintenance needs. Wet type fire hydrants cost less to install, with prices ranging from $1,500 to $3,500 per unit. Dry type hydrants cost more, from $2,000 to $4,500 per unit, due to their complex design. In warm regions, a wet type fire hydrant provides reliable and affordable fire protection. In cold areas, dry type hydrants ensure safe operation during freezing weather.

- Assess climate and freezing risk.

- Review local fire safety codes.

- Compare installation and maintenance costs.

- Plan hydrant placement for maximum coverage.

Choosing the right hydrant improves fire safety and protects property.

Best Practices for Outdoor Installation and Maintenance

Proper Placement for Maximum Coverage

Proper placement of wet type fire hydrants ensures fast and effective fire response. Installers must follow standards such as AWWA C600 and NFPA 24. Key guidelines include:

- Place hydrants close to streets for easy pumper access, using only one supply line length.

- Position the pumper nozzle to face the street; rotate the hydrant top if needed.

- Install hydrants at intersections for better visibility and access.

- Place hydrants on both sides of the street to avoid hoses crossing traffic.

- Follow hose lay distance recommendations: up to 250 feet in populated areas, up to 1,000 feet in less populated zones.

- Avoid placing hydrants directly in front of buildings to keep fire trucks in safe positions.

- Use barriers in open areas to protect hydrants from accidental damage.

- Set hose outlets about 18 inches above ground for easy access.

- Ensure proper drainage around the base with gravel or stone to prevent erosion.

Tip: Good placement improves safety and helps firefighters reach water quickly.

Routine Inspection and Upkeep

Routine inspection keeps hydrants reliable and ready for emergencies. Teams should check for leaks, damage, and obstructions. Regular flushing removes debris and ensures clear water flow. Lubricate moving parts to maintain smooth operation. Inspect caps and outlets for wear. Verify color coding matches flow capacity. Maintain detailed records of all inspections and repairs.

- Inspect visually and operationally each year.

- Flush hydrants annually to remove sediment.

- Test flow and pressure every five years.

- Lubricate stems and check drainage yearly.

Safety Considerations for Outdoor Settings

Safety protocols protect both equipment and personnel. The table below outlines key procedures:

| Safety Protocol Component | Frequency | Key Details |

|---|---|---|

| Visual Inspection | Annually | Check exterior, caps, outlets; ensure visibility and access. |

| Operational Inspection | Annually | Open hydrant fully; check for leaks or valve issues. |

| Hydrant Flushing | Annually | Remove debris by flushing; ensure clear water. |

| Flow Testing | Every 5 Years | Measure flow and pressure for compliance. |

| Lubrication of Operating Stem | Annually | Lubricate stem for smooth operation. |

| Drainage Check | Annually | Confirm proper drainage after use. |

| Hydrant Cap Inspection | Annually | Inspect caps for damage; check threads. |

| Color Coding Verification | Annually | Ensure color matches flow capacity; repaint if needed. |

| Pressure Testing | Every 5 Years | Confirm pressure during use. |

Immediate repairs keep hydrants ready for emergencies. Teams should coordinate with local fire departments for flow testing and maintain accurate maintenance records.

Wet type fire hydrants offer instant water access and dependable performance for outdoor fire safety in mild climates.

- Water remains available at all times, supporting quick emergency response.

- Each outlet operates independently, allowing multiple hoses during firefighting.

- Their design suits areas without freezing risk, making them a preferred choice for property owners.

FAQ

What is the main advantage of a wet type fire hydrant outdoors?

A wet type fire hydrant provides instant water access. Firefighters can connect hoses quickly and start firefighting without delay.

How often should outdoor wet type fire hydrants be inspected?

Experts recommend monthly visual inspections and annual flow testing. Regular checks help ensure the hydrant stays ready for emergencies.

Can the 2 Way Fire (Pillar) Hydrant connect to any standard fire hose?

Yes. The 2 Way Fire (Pillar) Hydrant features a 2.5-inch BS instantaneous outlet. This design fits most standard fire hoses used by fire departments.

Post time: Aug-21-2025