Portable Foam Inductors deliver rapid fire suppression in warehouse settings, outperforming hose reels and traditional water-based methods. Their thick foam blanket cools combustible surfaces and prevents reignition. Facilities often pair a Foam Branchpipe & Foam Inductor with a Dry Powder Fire Extinguisher or CO2 Fire Extinguisher for maximum coverage.

Key Takeaways

- Portable foam inductors provide fast, flexible fire suppression in warehouses, reaching fires in hard-to-access areas and adapting to different fire types.

- Adjustable foam concentrate ratios and compatibility with various foam types help optimize firefighting efforts and reduce waste.

- Regular maintenance, staff training, and quick deployment ensure portable foam inductors work effectively during emergencies.

Portable Foam Inductors and the Challenges of Warehouse Fires

Unique Fire Risks in Warehouses

Warehouses face many fire hazards that make them vulnerable to fast-spreading fires. Common risks include:

- Electrical malfunctions, such as faulty wiring and overloaded circuits

- Human error, like improper storage of flammable materials or ignoring safety rules

- Automated machinery problems, including overheating or battery hazards

- Heating equipment that is not maintained or placed safely

- Flammable packaging, chemicals, and large stockpiles

- Smoking, improper trash removal, and poor housekeeping

These hazards can lead to fires that grow quickly and are hard to control. Regular inspections, employee training, and clear safety policies help reduce these risks.

The Need for Mobility and Rapid Response

Large warehouses often have high racks, dense storage, and complex layouts. Fires can start in hard-to-reach places or spread through stacked goods. Quick action is critical. Delays in fire detection or response can cause major losses, as seen in past warehouse fires where slow notification led to millions in damages. Portable Foam Inductors allow firefighters to move quickly and reach the source of the fire, even in crowded or remote areas. Early detection and immediate use of mobile equipment help stop fires before they become unmanageable.

Tip: Training staff to notify emergency teams right away, instead of trying to fight large fires themselves, can save lives and property.

Limitations of Fixed Fire Suppression Systems

Fixed fire suppression systems, such as sprinklers, have limits in large or complex warehouses. These systems may not reach every area, especially in facilities with high racks or solid shelving. Integrating new systems with old infrastructure can be difficult and costly. Maintenance is also a challenge; without regular checks, fixed systems may fail during an emergency. Some high-risk materials, like lithium-ion batteries or aerosols, need special protection that standard sprinklers cannot provide. Portable Foam Inductors offer a flexible solution, filling gaps where fixed systems fall short.

Key Design Features of Portable Foam Inductors

Low-Pressure Drop and Balanced Performance

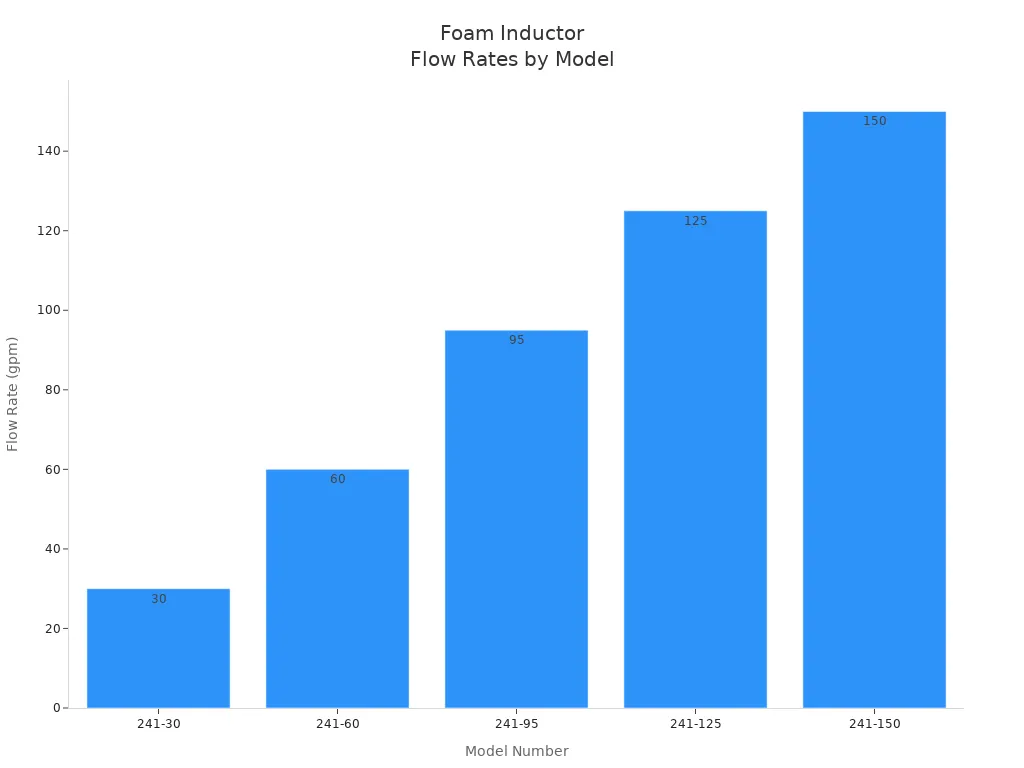

Portable Foam Inductors rely on efficient water flow and minimal pressure loss to deliver foam quickly during emergencies. Leading models, such as those from Elkhart Brass, operate at a standard inlet pressure of 200 psi. The following table shows the flow rates and pressure requirements for several popular models:

| Model Number | Flow Rate (gpm) | Flow Rate (LPM) | Inlet Pressure (psi) |

|---|---|---|---|

| 241-30 | 30 | 115 | 200 |

| 241-60 | 60 | 230 | 200 |

| 241-95 | 95 | 360 | 200 |

| 241-125 | 125 | 475 | 200 |

| 241-150 | 150 | 570 | 200 |

Most foam eductors experience a pressure drop of about 30% due to friction loss through the Venturi. Maintaining the correct flow rate is important for proper foam mixing and delivery. For example, the Angus Hi-Combat IND900 portable foam inductor provides a flow rate of 900 liters per minute at 7 bar (100 psi), with a typical pressure drop of 30-35%. These features ensure balanced performance, allowing firefighters to respond effectively in large warehouse spaces.

Yuyao World Fire Fighting Equipment Factory designs its Portable Foam Inductors to meet these demanding standards. Their products maintain consistent flow and pressure, supporting reliable foam application in critical situations.

Adjustable Flow and Induction Ratios

Firefighters often face different types of fires in warehouses, from flammable liquids to packaging materials. Adjustable flow and induction ratios make Portable Foam Inductors versatile tools for these scenarios. Many models allow users to set the foam concentrate ratio between 1% and 6%, matching the needs of each fire. This adjustment is usually made with a metering head or an easy-read knob, which helps teams quickly adapt to changing conditions.

- Adjustable foam concentrate ratios (1% to 6%) support various fire types.

- High flow rate capacity (up to 650 liters per minute at 6 bar) ensures strong firefighting performance.

- Stainless steel filters prevent debris from blocking the system, reducing maintenance needs.

- Durable aluminum alloy construction with corrosion resistance extends service life.

- 360-degree rotation prevents hose knotting and allows flexible positioning.

- Compatibility with multiple connection types (BS336, Storz, Gost) increases adaptability.

These features help conserve foam concentrate, reduce waste, and improve environmental safety. Yuyao World Fire Fighting Equipment Factory incorporates these design elements to ensure their Portable Foam Inductors perform reliably in both industrial and commercial environments.

Note: Proper adjustment of flow and induction ratios ensures the foam solution is optimized for each fire, improving efficiency and effectiveness.

Compatibility with Various Foam Concentrates

Warehouse fires often involve flammable liquids, plastics, or chemicals. Portable Foam Inductors must work with a range of foam concentrates to handle these risks. Most units, including those from Yuyao World Fire Fighting Equipment Factory, are compatible with common foam types such as AFFF (Aqueous Film-Forming Foam), AR-AFFF (Alcohol-Resistant AFFF), FFFP (Film-Forming Fluoroprotein), and fluorine-free foams.

In many warehouse applications, a 3% foam concentrate is standard, especially for AFFF or similar products. Units like the Endlessafe Mobile Foam Trolley and Forede Mobile Foam Unit use this concentration to generate effective foam blankets. No major compatibility issues have been reported with these foam types. Corrosion-resistant materials and adjustable proportioning ratios further support the use of different concentrates, making these inductors suitable for a wide range of fire hazards.

Tip: Always check the foam concentrate type and proportioning settings before use to ensure maximum performance and safety.

Operational Benefits and Practical Considerations of Portable Foam Inductors

Ease of Transport and Quick Deployment

Portable Foam Inductors offer significant advantages in mobility. The CHFIRE CH22-15 model weighs about 13.25 kg and measures only 700 mm in length. Its compact size allows emergency teams to carry and install it quickly without extra equipment. The packaging protects the unit during transport, making it easy to move around large warehouses. Larger units, such as the Fire FOAM Trolley Unit HL120, weigh more and come with wheels. These wheels help users move the heavier equipment across warehouse floors. Facility managers can select the right model based on the size of their warehouse and the need for speed during emergencies.

Accurate Foam Proportioning and Pressure Management

Portable Foam Inductors maintain reliable foam output during long firefighting operations. They use a pressurized water supply to mix foam concentrate and water at precise ratios. The design has no moving parts, which increases reliability and keeps pressure steady. Operators can adjust the foam concentrate rate from 1% to 6% using a metering valve. The following table highlights key features that support consistent performance:

| Feature | Description |

|---|---|

| Operating Pressure | 6.5-12 Bar (93-175 PSI) |

| Foam Concentrate Rate | Adjustable (1%-6%) |

| Maximum Back Pressure | Up to 65% of inlet pressure |

| Moving Parts | None |

| Body Material | Aluminum Alloy, Copper Alloy |

These features ensure that the foam solution remains effective, even during extended use.

Maintenance, Training, and Best Practices

Regular maintenance keeps Portable Foam Inductors ready for emergencies. Teams should check filters for debris and inspect hoses for leaks. Training staff on setup and operation ensures quick deployment. Best practices include storing the equipment in accessible locations and reviewing procedures during safety drills. Facility managers should schedule routine inspections and keep records of maintenance activities.

Tip: Simple checklists help staff remember key steps during both maintenance and emergencies.

Comparing Portable Foam Inductors to Fixed Systems

Advantages of Mobile Firefighting Solutions

Mobile firefighting solutions offer unique benefits in warehouse environments. Firefighters can move equipment quickly to the fire’s location, even in large or crowded spaces. This flexibility allows teams to respond to fires that start in hard-to-reach areas. Portable Foam Inductors stand out because they deliver foam over long distances, often reaching 18 to 22 meters at 7 bar pressure. Many models mix foam and water without extra pumps, making setup fast and simple.

- Teams can adjust flow rates during operation, which helps them adapt to changing fire conditions.

- Mobile units work with all types of foam concentrates, so they handle many fire risks, including oil fires.

- These systems keep working even if fixed equipment gets damaged during a fire.

- Firefighters can use longer hoses with mobile units, staying farther from danger while still fighting the fire.

- Mobile systems also support environmental safety by allowing foam recirculation during testing.

Note: Mobile solutions often require less manpower and can be deployed rapidly, which is critical when every second counts.

Limitations and When Fixed Systems Are Preferred

Fixed fire suppression systems still play an important role in warehouse safety. They provide automatic protection and cover large areas without human intervention. In some cases, fixed systems offer faster initial response, especially when fires start at night or when staff are not present. These systems work well in warehouses with simple layouts and predictable fire risks.

However, fixed systems have limits. They cannot reach every corner, especially in complex or high-rack storage areas. They may also struggle with pressure and flow changes, which can affect foam quality. Facility managers often use a combination of fixed and mobile solutions to ensure complete coverage and rapid response.

Portable foam inductors deliver flexible fire protection for warehouses, adapting to many hazards. Firefighters use these systems in incidents involving plastics, paints, or adhesives.

- Future trends include robotics, smart devices, and electric vehicles for safer, more efficient firefighting.

- Ongoing innovation and market growth will drive better solutions.

FAQ

What types of foam concentrates work with portable foam inductors?

Most portable foam inductors support AFFF, AR-AFFF, FFFP, and fluorine-free foams.

Always check the manufacturer’s specifications for compatibility.

How often should teams inspect portable foam inductors?

Teams should inspect portable foam inductors monthly.

- Check filters for debris

- Inspect hoses for leaks

- Review proportioning settings

Can one person operate a portable foam inductor?

Yes, one trained person can operate most portable foam inductors.

Training ensures safe and effective use during emergencies.

Post time: Jul-14-2025