The number of outlets on a fire hydrant, such as a Two Way Fire Hydrant or 2 Ways Fire Hydrant, directly shapes water supply and firefighting options. A 2 Way Pillar Hydrant, also called a Two Way Pillar Fire Hydrant or Double Outlet Fire Hydrant, supports two hoses for efficient fire control in low-rise buildings.

Key Takeaways

- Two way fire hydrants support up to two hoses and fit well in small buildings or areas with limited space, offering reliable water flow for quick firefighting.

- Three way fire hydrants allow connection of three hoses, providing higher water flow and flexibility, ideal for large buildings, industrial sites, and complex emergencies.

- Regular inspection and maintenance keep fire hydrants functional and accessible, ensuring fast and effective emergency response when it matters most.

Two Way Fire Hydrant vs Three Way Fire Hydrant: Quick Comparison

Key Features and Specifications

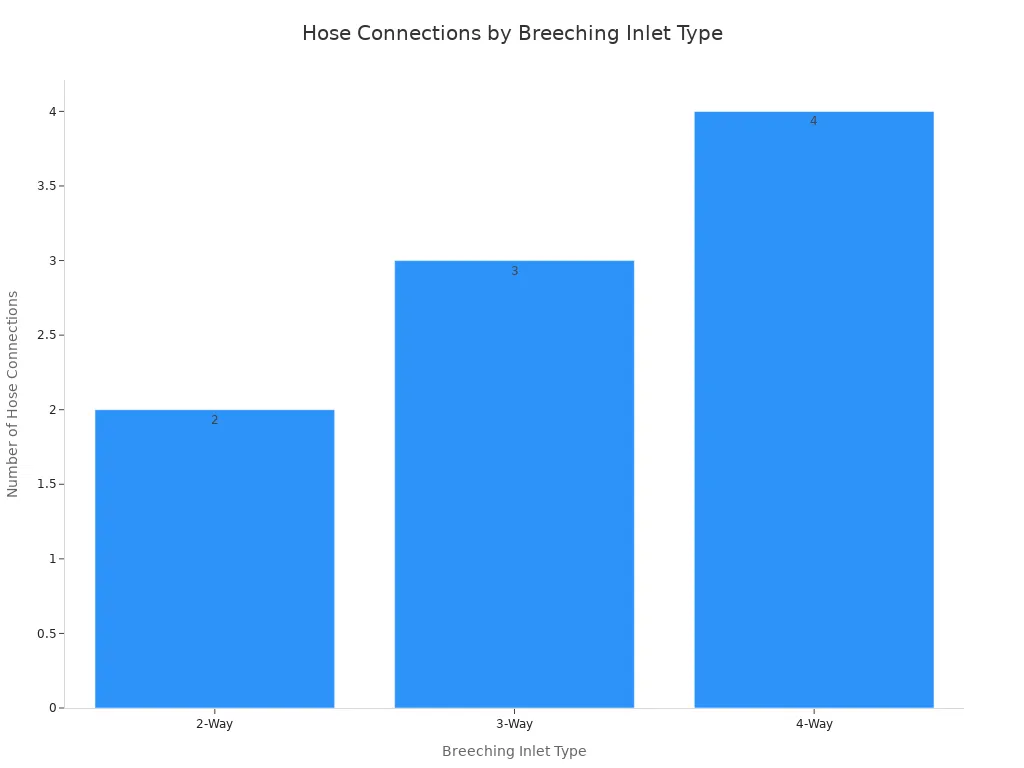

When comparing fire hydrants, the number of outlets stands out as a major difference. The table below highlights the main features and specifications of each type:

| Feature | Two Way Fire Hydrant | Three Way Fire Hydrant |

|---|---|---|

| Number of Outlets | 2 | 3 |

| Typical Use | Small to medium buildings | Large buildings, complexes |

| Water Flow Capacity | Moderate | High |

| Hose Connections | Up to 2 hoses | Up to 3 hoses |

| Installation Space | Less required | More required |

| Maintenance | Simple | Slightly more complex |

Tip: Firefighters often choose a Two Way Fire Hydrant for areas with limited space or lower water demand. Three way models work better in places where more hoses and higher water flow are needed.

Each hydrant type serves a specific purpose. Two way models fit well in residential zones or small commercial sites. Three way hydrants support larger teams and more equipment during emergencies.

Two Way Fire Hydrant: Detailed Differences

Design and Structure

A Two Way Fire Hydrant features a robust design that prioritizes durability and operational reliability. Manufacturers like Yuyao World Fire Fighting Equipment Factory use advanced materials and construction standards to ensure long service life. The hydrant body typically consists of cast iron, which provides structural strength and resists high pressure and impact. Internal components such as valves and operating rods use corrosion-resistant bronze or brass. Seals and gaskets made from rubber or synthetic materials prevent leaks and wear. The hydrant includes a drain valve to remove residual water, reducing the risk of freeze damage in cold climates. An epoxy internal coating protects against corrosion and environmental wear.

| Aspect | Specification / Standard |

|---|---|

| Pipe Materials | PVC (AWWA C-900), Ductile Iron Pipe, Cast Iron Pipe |

| Valves | Gate Valves (AWWA C500), nonrising stem, buried service |

| Valve Boxes | Traffic type, cast iron |

| Fire Hydrants | AWWA C502; 5 1/4-inch main valve; two 2 1/2-inch nozzles; one 4 1/2-inch nozzle; National Standard threads; chrome yellow finish |

| Water Line Fittings | Cast or ductile iron |

| Installation Methods | Trenching, backfilling, compaction testing |

| Testing and Disinfection | Pressure/leakage testing (AWWA C600); Disinfection (AWWA C601) |

The internal structure includes tamper-resistant operating nuts and ergonomic design for ease of use. Self-draining features and break-away designs protect both the hydrant and underground infrastructure, supporting a service life of over 50 years with proper maintenance.

Water Output and Flow Capacity

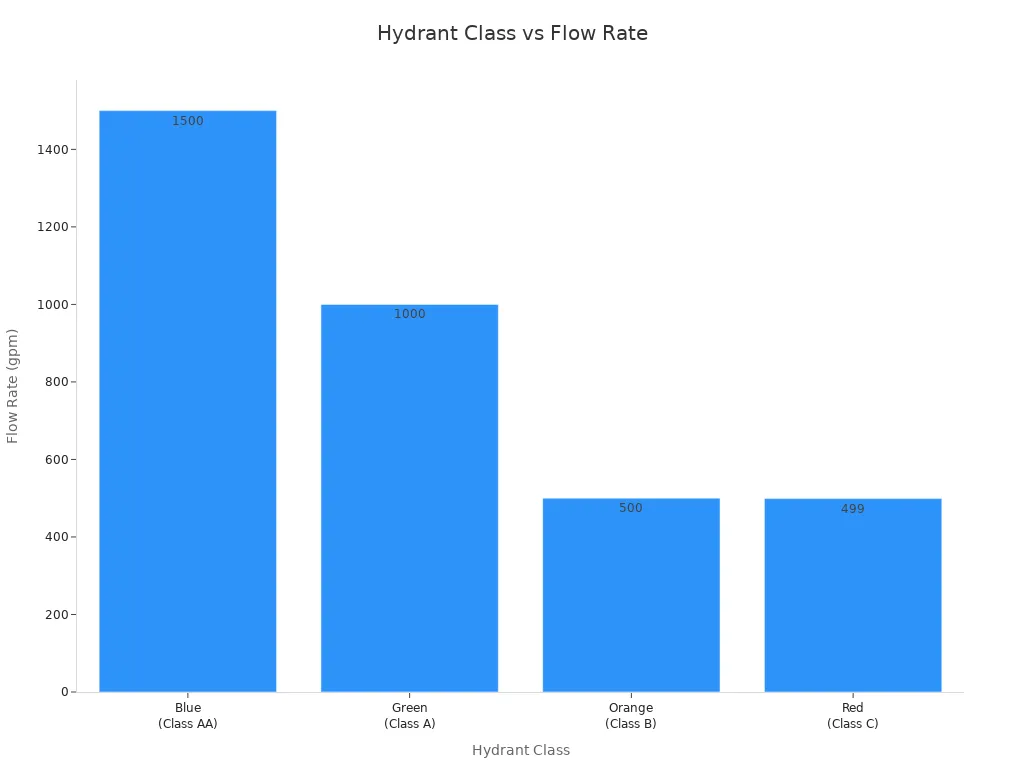

The Two Way Fire Hydrant delivers reliable water output suitable for most urban and suburban firefighting needs. In typical scenarios, each hydrant supports flow rates from 500 to 1,500 gallons per minute (gpm). This range meets the requirements for effective fire suppression in small to medium buildings. The hydrant usually has two 2½-inch outlets and one 4½-inch steamer connection, allowing firefighters to connect multiple hoses and maximize water delivery.

| Parameter | Details / Range |

|---|---|

| Typical flow rate | 500 to 1,500 gpm |

| Discharge outlets | Two 2½-inch, one 4½-inch steamer |

| Hydrant flow classification | Blue: ≥1,500 gpm; Green: 1,000–1,499 gpm; Orange: 500–999 gpm; Red: <500 gpm |

| Water main sizes | Minimum 6 inches; commonly 8 inches or larger |

| Flow rates by main size | 6-inch: up to 800 gpm; 8-inch: up to 1,600 gpm |

| Hydrant spacing (urban) | Residential: 400–500 ft; Commercial: 250–300 ft |

| Operational notes | All outlets flowing; steamer connection increases flow |

Multiple outlets allow the hydrant to split flow, reducing friction loss and maintaining higher residual pressure at the supply engine. This design supports high-demand conditions better than single-outlet hydrants, enabling firefighters to operate closer to the hydrant’s rated capacity.

Installation and Space Requirements

Proper installation of a Two Way Fire Hydrant ensures accessibility and compliance with safety codes. City planning documents specify several key requirements:

- Hydrant types and hose thread styles must match local authority standards.

- The maximum distance from a hydrant to any part of a sprinklered building’s ground floor is typically 600 feet.

- Hydrants must be at least 40 feet from the building face.

- Local authorities may adjust spacing based on site conditions.

- In congested areas, coordination with fire officials is essential to address collapse zones and nearby structures.

- Hydrants in high-traffic or damage-prone areas require protective bollards that do not block operation.

- Isolation control valves must be within 20 feet of the hydrant.

- Post-indicator valves are preferred in cold climates and should be placed outside roadways.

The installation process remains similar in residential and industrial settings. Both environments require selecting an accessible location, preparing the installation pit, connecting to the water line, checking drainage, leveling, pressure testing, and backfilling. However, residential areas often use hydrants rated for lower pressure (PN10), while industrial sites require higher ratings (PN16) to meet greater demand.

Early collaboration among fire protection designers, civil engineers, and local fire authorities helps avoid costly redesigns and ensures compliance.

Maintenance and Operation

Routine maintenance keeps a Two Way Fire Hydrant ready for emergencies. Fire safety authorities recommend the following schedule:

- Inspect hydrants annually to confirm working condition.

- Perform weekly visual checks for damage, rust, or obstructions.

- Examine nozzle caps, operating nuts, and valves for corrosion or wear.

- Test water flow to measure static and residual pressure and verify performance.

- Check mechanical parts, lubricate moving components, and ensure smooth operation.

- Document all inspections and tests for compliance and future planning.

Common operational challenges include missing or damaged hydrants, difficult-to-remove caps, frozen or broken units, and obstructions like snow or parked vehicles. Unauthorized use or vandalism can also impair function. Regular inspection and prompt maintenance help address these issues, ensuring hydrants remain accessible and functional during emergencies.

Yuyao World Fire Fighting Equipment Factory provides technical support and high-quality hydrants designed for easy maintenance and reliable operation, helping communities maintain effective fire protection systems.

Three Way Fire Hydrant: Detailed Differences

Design and Structure

A three way fire hydrant features a robust and versatile design that supports complex firefighting operations. The hydrant body uses high-strength materials such as ductile iron or cast iron, which provide durability and resistance to impact. Manufacturers like Yuyao World Fire Fighting Equipment Factory engineer these hydrants to meet strict industry standards, ensuring long service life and reliable performance.

- The three-way valve or manifold allows firefighters to connect multiple supply lines at the same time, increasing both water supply capacity and operational flexibility.

- Firefighters can add or remove hoses without interrupting the water flow to existing lines. This feature proves critical during large-scale emergencies.

- The design supports dual supply lines feeding separate rigs or locations, which is essential in complex fireground scenarios such as apartment complexes or industrial parks.

- Gate valves on side discharges further increase capacity and versatility, especially when access to the main steamer connection is limited.

- The hydrant’s configuration allows fire departments to maximize capacity, support multiple attack pumpers, and adapt to different access points without shutting down the water source.

Note: This flexibility provides redundancy and improved positioning of attack lines, which enhances operational effectiveness during emergencies.

Water Output and Flow Capacity

Three way fire hydrants deliver high water output, making them ideal for large-scale firefighting operations. Their design supports simultaneous multi-hose connections, which increases the total water flow available to firefighters.

- Triple tapped three-way hydrants can achieve flow rates up to approximately 2,700 gallons per minute (gpm) while maintaining safe residual pressures.

- At this flow rate, the residual intake pressure at the pumper remains about 15 psi, and the pressure at the hydrant stays around 30 psi. These values comply with municipal and AWWA guidelines.

- When using large-diameter hoses (such as 5-inch LDH) on all outlets, friction loss decreases and residual intake pressure increases, allowing higher flow rates.

- The main valve size, typically about 5¼ inches, limits the maximum flow rather than the number of outlets.

- Field tests show that adding a third 5-inch supply line increases residual intake pressure, which improves flow efficiency.

Firefighters often connect multiple large-diameter hoses to all available outlets. This approach allows rapid initial water supply and system expansion, which is vital for managing large fires. The ability to supply several hoses at once increases operational flexibility and ensures that teams can respond quickly to changing fire conditions.

Installation and Space Requirements

Proper installation of three way fire hydrants ensures accessibility and compliance with safety codes, especially in commercial developments and high-density areas.

- Hydrants must be complete assemblies, including the hydrant, watch valve, valve box, piping, and all necessary appurtenances.

- The hydrant should be a compression type, meeting AWWA C502 standards, with specific nozzle sizes and opening direction.

- Traffic models require a breakaway flange set 3 inches above to 3 inches below finished grade for safety.

- The distance from the road to the hydrant should be 3 to 8 feet if a curb exists, or 5 to 8 feet if there is a ditch and hydrant approach.

- Hydrants should be located at intersections and spaced every 300 to 350 feet for optimal coverage.

- Placement on property lines of adjacent parcels ensures shared access.

- Installation involves trenching to specified depths, using Class 52 ductile iron piping, and backfilling with No. 57 washed gravel to prevent corrosion.

- Where ditches exist, hydrant approaches must include reinforced concrete pipe culverts and proper bedding.

- All disturbed earth areas from installation must be seeded according to local standards.

Tip: Yuyao World Fire Fighting Equipment Factory provides technical support and guidance for proper hydrant installation, helping ensure compliance with local codes and long-term reliability.

Maintenance and Operation

Three way fire hydrants require regular maintenance to ensure they remain functional and accessible, especially in high-traffic urban areas.

- Inspect hydrants at least twice a year to confirm they are operational and clearly visible.

- Apply bright, reflective paint and clear markings to enhance visibility, especially in poor lighting or adverse weather.

- Enforce parking regulations to prevent vehicles from blocking hydrant access.

- Promote community awareness programs to educate the public about the importance of keeping hydrants unobstructed and reporting issues.

- Implement winter preparedness measures, such as snow removal around hydrants, to maintain accessibility in snowy climates.

- Manage urban clutter and vegetation by trimming overgrown plants and removing debris that could obscure hydrants.

- Ensure hydrants are strategically placed within close distances in commercial and residential areas for quick emergency access.

Common operational issues include low water pressure, leaks at valves or nozzles, frozen hydrants in cold climates, and obstructions from vegetation or debris. Regular inspection, lubrication, and testing help address these problems and keep hydrants ready for emergencies.

Callout: Consistent maintenance and community cooperation ensure that three way fire hydrants provide reliable water supply and support effective firefighting response when every second counts.

Two Way Fire Hydrant in Real-World Uses

Typical Applications of Two Way Fire Hydrant

A Two Way Fire Hydrant serves as a reliable water source in many urban and suburban settings. Fire departments often install these hydrants in residential neighborhoods, small commercial areas, and low-rise buildings. The compact design fits well in places with limited space or narrow streets. Many schools, hospitals, and shopping centers rely on this hydrant type for quick emergency response.

Fire safety planners choose the Two Way Fire Hydrant for its balance of water flow and ease of installation. The hydrant supports two hoses at once, allowing firefighters to attack a fire from different angles or supply water to multiple teams. This flexibility helps protect property and save lives in smaller-scale emergencies.

Case Examples for Two Way Fire Hydrant

During the Garden Fire near Fallbrook, California, in November 2019, a specialized two-way hydrant system played a vital role in wildfire suppression. The Rapid Aerial Water Supply system, known as the ‘Heli-Hydrant,’ allowed helicopter pilots to collect up to 5,000 gallons of water in just two minutes. Crews completed nearly 30 aerial water drops, which helped control the fast-moving brush fire. The quick access to water protected homes and prevented structural losses. Fire officials credited the system with enabling rapid and effective firefighting, especially under challenging conditions with strong winds and dry vegetation. This example shows how a Two Way Fire Hydrant can support both ground and aerial firefighting operations, making it a valuable tool in emergency response.

Three Way Fire Hydrant in Real-World Uses

Typical Applications of Three Way Fire Hydrant

Three way fire hydrants play a vital role in protecting large and high-risk environments. Their design supports multiple hose connections, making them ideal for areas that require fast and flexible firefighting responses. Common applications include:

- Industrial parks and factory perimeters, where wall hydrants provide quick access during electrical or chemical fires.

- Commercial buildings and parking garages, which need reliable water sources for fire emergencies.

- Industrial complexes that store flammable materials or operate heavy machinery.

- Residential and downtown areas, where pillar hydrants ensure coverage for densely populated spaces.

- Marine and waterfront locations, such as ports and docks, where deck hydrants help control fires on ships or piers.

In industrial settings, fire hydrant systems address higher fire risks from chemicals and machinery. These systems often feature outdoor hydrants with large water storage and advanced pumps. Warehouses use both indoor and outdoor hydrants to control fires before they spread.

Deluge hydrant systems deliver instant, high-volume water flow in dangerous areas like chemical plants and oil refineries. This rapid response helps protect people and property in high-risk locations.

Case Examples for Three Way Fire Hydrant

A large industrial park in Houston, Texas, uses three way fire hydrants along its perimeter. When a warehouse fire broke out, firefighters connected hoses to all three outlets. This setup allowed teams to attack the fire from different sides and supply water to multiple engines. The quick response stopped the fire from spreading to nearby buildings.

In a busy port city, deck hydrants with three outlets helped firefighters control a shipboard fire. Crews connected hoses to the hydrant and reached both the dock and the vessel. The flexible water supply made it possible to contain the blaze and prevent damage to other ships. These examples show how three way fire hydrants support complex firefighting operations in real-world scenarios.

Choosing Between Two Way Fire Hydrant and Three Way Fire Hydrant

Factors to Consider

Selecting the right fire hydrant type requires careful evaluation of several important factors. Fire safety planners look at the size of the area, the expected water demand, and the types of buildings present. They also consider the number of fire hoses that may need to operate at the same time.

- Water Flow Needs: High-density residential areas and industrial zones often need a higher water flow rate. For example, experts recommend a flow rate of 30 liters per second for both high-density residential and commercial or industrial areas, with a supply duration of four hours. Low-density residential zones usually require only 15 liters per second for two hours.

- Space and Accessibility: Some locations have limited space for installation. A Two Way Fire Hydrant fits well in narrow streets or small lots. Three way hydrants need more room but offer greater flexibility for large teams.

- Building Type and Risk Level: Industrial parks, factories, and commercial complexes face higher fire risks. These areas benefit from hydrants that can support multiple hoses and deliver large volumes of water quickly.

- Climate and System Type: In cold climates or unheated spaces, dry pipe systems prevent freezing. Wet pipe systems work well in general residential areas. Deluge systems suit high-hazard environments, such as chemical plants, where rapid water delivery is critical.

Fire departments should match the hydrant type to the specific needs of the area. This approach ensures reliable water supply and effective emergency response.

Two Way Fire Hydrant models offer reliable water flow for smaller buildings, while three way hydrants serve larger, high-risk areas. Fire safety experts recommend choosing hydrant types based on building size, water demand, and local codes. Communities should ensure hydrants remain visible, accessible, and regularly maintained for effective emergency response.

- Internal hydrant systems suit high-rises.

- External hydrants fit urban and industrial zones.

- Proper placement and regular testing improve safety.

FAQ

What is the main advantage of a three way fire hydrant?

A three way fire hydrant allows firefighters to connect more hoses. This feature increases water flow and supports larger firefighting teams during emergencies.

Can a two way fire hydrant be upgraded to a three way model?

No, upgrading a two way hydrant to a three way model requires replacing the entire unit. The design and structure differ significantly.

How often should fire hydrants undergo maintenance?

Fire safety experts recommend inspecting and maintaining hydrants at least once a year. Regular checks ensure reliable operation and quick emergency response.

Post time: Jul-22-2025