The Pressure Reducing Valve E Type plays a crucial role in maintaining consistent water pressure for fire hydrants. It effectively prevents damage to hydrant systems caused by fluctuations in pressure. With enhanced performance, this Water Pressure Reducing Valve significantly improves safety during fire emergencies. Additionally, the Pressure Reducing Landing Valve and Pressure Reducing Regulator Valve are essential components that further ensure reliable operation in critical situations.

Importance of Pressure Reducing Valves

Role in Fire Hydrant Systems

Pressure reducing valves (PRVs) serve essential functions in fire hydrant systems. They regulate water pressure, ensuring that it remains within safe limits. This regulation is crucial for protecting both firefighters and property from potential damage caused by high-pressure water. The following table outlines the main functions of pressure reducing valves in fire hydrant systems:

| Function Description |

|---|

| Reducing system pressure and relieving it. |

| Lowering pressure levels from the main circuit to the sub-circuit. |

| Regulating system pressure in specific parts of the circuit. |

| Preventing the maximum system pressure from reaching an unsafe level. |

| Protecting the system from excessive system pressures. |

| Maintaining high pressures even with varying input pressures. |

By maintaining stable pressure levels, PRVs help reduce the risk of leaks and pipe bursts. They have been shown to decrease leakage rates by 31.65%, minimizing water wastage. Furthermore, the implementation of PRVs leads to fewer pipe breaks, which lowers repair and replacement costs. This reliability ensures that the water supply system remains uninterrupted during emergencies.

Impact on Water Pressure Consistency

Water pressure consistency is vital for the effectiveness of fire hydrant systems during emergencies. High water pressure can damage critical components, leading to equipment failure. Fluctuating pressure disrupts firefighting operations, making it challenging for firefighters to maintain a steady water stream. Excessive pressure can also alter the spray patterns of sprinklers or nozzles, reducing their effectiveness and delaying fire extinguishment.

The recommended pressure range for fire hydrant operation, according to industry standards, emphasizes the importance of maintaining consistent pressure. For instance, NFPA 24 (2019) indicates that systems without a fire pump typically do not exceed 150 PSI in underground piping. Additionally, NFPA 291 recommends maintaining a residual pressure of 20 PSI for effective firefighting.

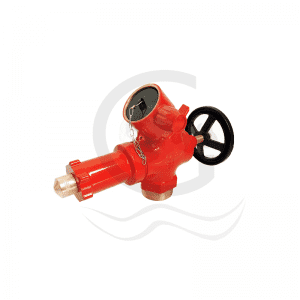

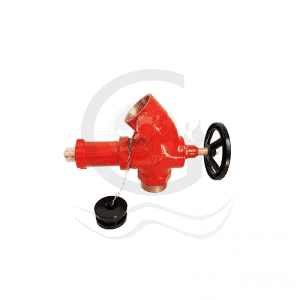

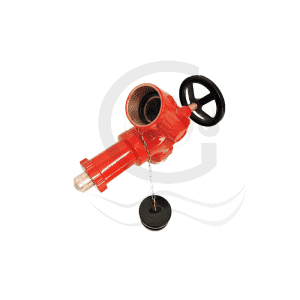

Features of the Pressure Reducing Valve E Type

Design and Functionality

The E Type Pressure Reducing Valve boasts a robust design tailored for optimal performance in fire hydrant systems. Its construction utilizes high-quality brass, ensuring durability and resistance to corrosion. The valve features a flanged or screwed inlet, allowing for versatile installation options.

Key design specifications include:

| Feature | Details |

|---|---|

| Material | Brass |

| Inlet | 2.5” BSPT |

| Outlet | 2.5” female BS instantaneous |

| Working pressure | 20 bar |

| Reduced outlet static pressure | 5 bar to 8 bar |

| Constant outlet pressure | 7 bar to 20 bar |

| Test pressure | Body test at 30 bar |

| Minimum flowrate | Up to 1400 L/M |

The E Type valve regulates water pressure by adjusting the flow from the main water supply. It automatically opens or closes in response to changes in inlet pressure to maintain steady outlet pressure. This mechanism ensures a reliable stream of water for firefighters, regardless of fluctuations in system pressure.

Durability and Reliability

Durability is a hallmark of the E Type Pressure Reducing Valve. Under normal operating conditions, this valve has an average lifespan of approximately eight years. However, this lifespan can vary based on maintenance practices and operating conditions. Regular maintenance, such as overhauls every two to four years, can significantly extend the valve’s operational life.

The E Type valve’s reliability stems from its rigorous testing process. Each valve undergoes a body test at 30 bar, confirming its ability to withstand high-pressure scenarios. This level of testing provides peace of mind for users, knowing that the valve will perform effectively during critical firefighting operations.

In comparison to other pressure reducing valve types, the E Type offers a simple design with fewer parts, making it an economical choice. However, it is essential to note that it may have limitations in shut-off pressure and actuator speed. These factors make it suitable primarily for applications with slow load changes.

Overall, the E Type Pressure Reducing Valve stands out for its combination of effective design, reliable performance, and durability, making it an essential component in fire hydrant systems.

Installation and Maintenance of the E Type Valve

Best Practices for Installation

Proper installation of the E Type Pressure Reducing Valve is crucial for optimal performance. Following best practices can prevent common installation errors. Here are key points to consider:

- Vertical Installation: Always install the valve vertically to avoid performance issues and ensure proper drainage.

- Support Discharge Piping: Ensure that discharge piping supports its own weight. This prevents stress on the valve, which can affect its operation.

- Maintain Pressure Differential: Keep a proper differential between operating and set pressure. This is vital for the valve’s performance.

Using the right tools also enhances installation efficiency. Recommended tools include:

- Pressure gauge

- Pipe wrench

- Tubing cutter

- Open-ended wrench

- Screwdriver

Routine Maintenance Tips

Routine maintenance is essential for the longevity and reliability of the E Type valve. Regular checks help identify potential issues before they escalate. The following table outlines recommended maintenance tasks and their frequency:

| Frequency | Maintenance Task |

|---|---|

| Monthly | Perform a visual inspection of the valve and piping. Clean the Y-strainer and orifice. |

| Quarterly | Check the PRP diaphragm and replace if necessary. Inspect the main valve diaphragm and seat packing for wear. |

| Annually | Conduct a comprehensive inspection of all valve components. Replace any worn or damaged parts to ensure optimal performance. |

Effective maintenance practices include:

- Regular inspections to identify potential problems.

- Cleaning and lubrication of moving parts to prevent wear.

- Monitoring for leaks to ensure system integrity.

By adhering to these installation and maintenance guidelines, users can ensure that the E Type Pressure Reducing Valve operates efficiently, providing reliable water pressure during critical firefighting operations.

The E Type Pressure Reducing Valve significantly enhances fire hydrant performance and safety. Consistent pressure management ensures reliable emergency response. Investing in E Type valves proves beneficial, as they reduce leakage and pipe breaks, which minimizes disruptions and protects infrastructure. This investment is crucial for effective fire safety systems.

FAQ

What is the primary function of the E Type Pressure Reducing Valve?

The E Type Pressure Reducing Valve regulates water pressure, ensuring consistent flow for fire hydrants during emergencies.

How often should the E Type valve be maintained?

Routine maintenance should occur monthly, quarterly, and annually to ensure optimal performance and longevity.

Can the E Type valve be installed in various environments?

Yes, the E Type valve is versatile and suitable for both internal and external fire protection applications.

Post time: Sep-10-2025