A Fire Hydrant connects directly to underground water mains, delivering high-pressure water where firefighters need it most. The Fire Hydrant Valve controls water flow, allowing rapid response. Fire ExtinguisherPillar Fire Hydrant designs ensure firefighters access water quickly, helping to protect lives and property during emergencies.

Key Takeaways

- Fire hydrant systems connect to underground water mains and use valves and outlets to deliver high-pressure water quickly to fight fires effectively.

- Firefighters follow specific steps and use special tools to open hydrants and connect hoses, ensuring fast and safe water flow during emergencies.

- Regular maintenance and testing of fire hydrants keep them reliable, prevent failures, and help protect communities by ensuring water is always ready when needed.

Fire Hydrant System Components and Water Flow

Fire Hydrant Water Supply and Underground Pipes

A Fire Hydrant system relies on a steady water supply from underground pipes. These pipes connect to city water mains, tanks, or natural sources. The pipes must deliver water quickly and at high pressure during emergencies. Most urban systems use a looped main supply, which forms a complete circuit. This design allows water to reach hydrants from multiple directions, keeping pressure stable even if one section needs repair. Isolation valves and check valves help control flow and prevent backflow.

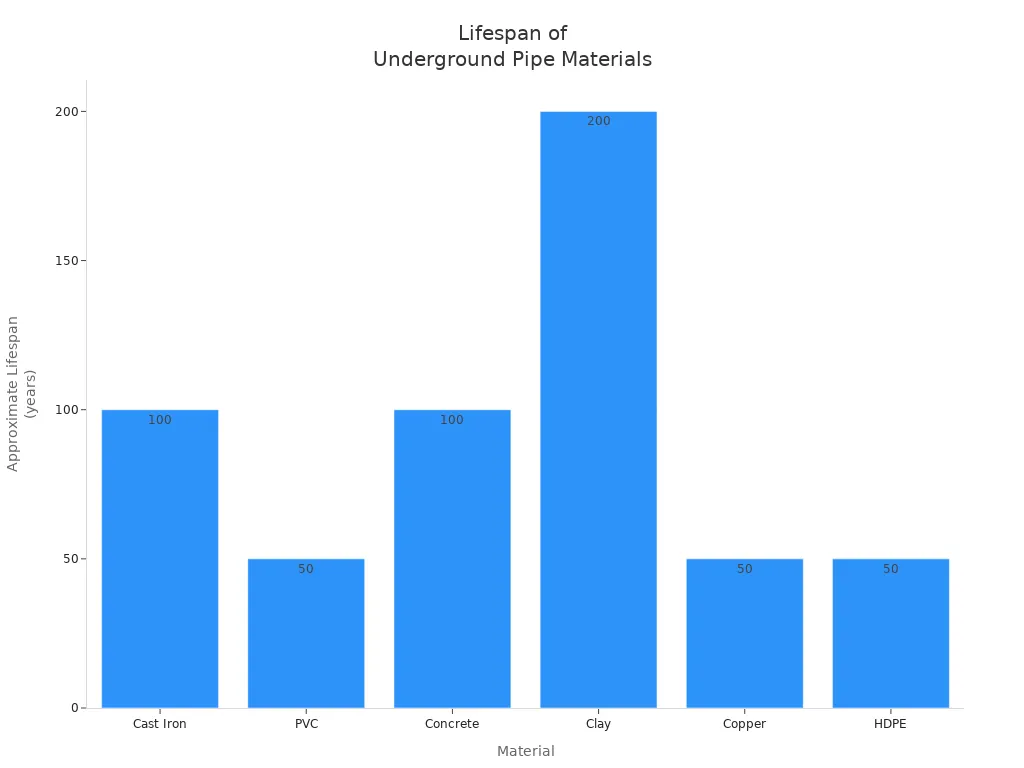

Materials for underground pipes vary. Cast iron and concrete can last up to 100 years but may face corrosion or cracking. PVC, copper, and HDPE pipes resist corrosion and root intrusion, with lifespans around 50 years. Clay pipes can last for centuries but may break if roots grow into them.

Fire Hydrant Body, Valves, and Outlets

The body of a Fire Hydrant houses several important parts. The barrel provides a passage for water, while the stem connects the operating nut to the valve. The valve controls water flow from the main pipe to the outlets. In cold climates, dry barrel hydrants keep water below ground to prevent freezing. Wet barrel hydrants, used in warmer areas, always have water up to the outlets.

A table below shows how each part contributes to water flow:

| Hydrant Part | Contribution to Water Flow |

|---|---|

| Nozzle Caps | Protect outlets from debris, ensuring clear water flow when hoses connect. |

| Barrel | Houses the stem and allows water to move above and below ground. |

| Stem | Connects the operating nut to the valve, opening or closing water flow. |

| Valve | Opens to let water flow or closes to stop it and drain the hydrant. |

| Outlets | Provide connection points for hoses; their size and number affect flow rate. |

Fire Hydrant Hose Connections and Access Points

Hose connections and access points play a key role in firefighting speed and efficiency. In North America, hydrants use threaded connections, usually 2.5-inch and 4.5-inch outlets. European hydrants often use Storz fittings, which allow quick, threadless connections. Adapters help connect hoses with different standards, making mutual aid between departments easier.

Proper hydrant placement and access design help firefighters deploy hoses quickly. Features like 2 Way Y Connections allow multiple hoses to operate at once, improving adaptability. Quick-connect couplings and multi-hose devices reduce setup time. Regular training ensures firefighters use these tools effectively during emergencies.

Fire Hydrant Operation and Effectiveness

How Firefighters Access and Open a Fire Hydrant

Firefighters follow a precise sequence when responding to a fire. This process ensures safety and maximizes efficiency:

- Notify emergency services and relevant personnel immediately after detecting a fire.

- Proceed to the nearest fire hydrant.

- Open the main control valve to activate the hydrant system.

- Open the hydrant outlet valve.

- Connect fire hoses securely to the hydrant outlet.

- Coordinate with the incident commander and emergency teams to determine water flow and deployment.

- Follow firefighting protocols, including wearing protective gear and maintaining safe distances.

- Direct water flow to the base of the fire using appropriate nozzles.

- Monitor and adjust water pressure and flow rates as needed.

- After extinguishing the fire, close the hydrant outlet valve and then the main control valve.

- Inspect all equipment for damage and document findings.

- Replenish and store used hoses and equipment.

- Review the operation with involved personnel to identify lessons learned.

Firefighters use a special pentagonal wrench to remove the valve cover before attaching hoses and opening the valve. A typical hydrant bag contains a hydrant wrench, rubber mallet, spanners, and a curb valve key. In some regions, the hydrant valve stem may turn clockwise or counterclockwise, so firefighters must know the local standard. Proper training and the right tools help crews open hydrants quickly, even under pressure.

Tip: Regular drills and equipment checks help firefighters avoid delays caused by stuck caps or incompatible fittings.

Connecting Hoses and Operating Fire Hydrant Valves

After opening the hydrant, firefighters connect hoses to the outlets. North American hydrants often use threaded connections, while European models may use Storz connectors for faster attachment. Firefighters must ensure a tight seal to prevent leaks and maintain water pressure. They use gate valves or butterfly valves to control water flow. Hydrant valves should be operated fully open or closed to avoid internal damage.

Common challenges during this stage include:

- Low water pressure from clogged pipes or malfunctioning valves.

- Frozen hydrants in cold weather.

- Damaged components from accidents or wear.

- Stuck hydrant caps or incompatible fittings between departments.

Firefighters carry adapters and specialized tools to address these issues on scene. Good communication and training help teams switch to backup hydrants if needed, ensuring a steady water supply.

Directing Water from Fire Hydrant to the Fire

Once hoses are connected, water flows from the fire hydrant to the fire scene. Firefighters may attach hoses directly to the hydrant or route them through a fire engine to boost pressure and split flow. The following table summarizes key aspects of this process:

| Aspect | Description |

|---|---|

| Water Direction | Hose attaches to hydrant; valve opened for flow. Hose may connect to fire engine for extra boost. |

| Valves Used | Gate or butterfly valves control flow; hydrant valves operated fully open or closed. |

| Hydrant Types | Wet barrel hydrants allow individual outlet control; dry barrel hydrants operate all outlets. |

| Hydrant Outlets | Multiple outlets; larger ‘steamer’ outlet often uses Storz connector; smaller outlets use threads |

| Connection Types | Threaded, quick connectors, Storz connectors. |

| Operational Precautions | Avoid opening/closing valves too quickly to prevent water hammer. PPE required. |

| Valve Installation | Valves on outlets allow individual flow control and equipment changes. |

| Firefighter Training | Crews trained to connect hydrants quickly, usually within one minute. |

Best practices for maximum water delivery include using large-diameter hoses (LDH), implementing looped supply line operations, and employing dual pumping techniques. These methods help maintain high flow rates and reliable water supply during large-scale fires.

Types of Fire Hydrant: Wet Barrel and Dry Barrel

Fire hydrants come in two main types: wet barrel and dry barrel. Each type suits different climates and operational needs.

| Feature | Wet Barrel Hydrant | Dry Barrel Hydrant |

|---|---|---|

| Water Presence | Always filled with water inside the barrel. | Water stored underground; enters hydrant only when valve opened. |

| Operation Speed | Faster operation; quick deployment. | Slightly slower initial water access due to valve operation. |

| Climate Suitability | Ideal for warm climates (e.g., southern U.S., tropical). | Suitable for cold climates (e.g., northern U.S., Canada). |

| Pros | Easy to operate; multiple valves for independent hose use. | Resistant to freeze damage; durable in winter conditions. |

| Cons | Prone to freezing and bursting in cold weather. | More complex to operate; requires training. |

- Wet barrel hydrants are common in warm or temperate climates where freezing is rare. They provide immediate water supply, which is vital in wildfire-prone areas.

- Dry barrel hydrants are designed for cold climates. Their valves sit below the frost line, draining water after use to prevent freezing. These hydrants are often found in rural, agricultural, or industrial regions.

Yuyao World Fire Fighting Equipment Factory manufactures both wet and dry barrel hydrants, ensuring reliable performance in any environment.

Fire Hydrant Water Pressure and Flow Rate

Municipal fire hydrants typically operate at a working pressure of around 150 psi. Some systems can reach up to 200 psi, while special industrial hydrants may handle pressures as high as 250 psi. Pressures above 175 psi require special equipment or pressure regulation for safe use. Manual firefighting nozzles usually operate at 50 to 100 psi, so firefighters must manage high supply pressures carefully.

Adequate water flow rate is critical for effective firefighting, especially during large-scale incidents. Using large-diameter hoses reduces friction loss and increases available water. Heavy hydrant hookups, such as double or triple tapping, further boost flow and provide redundancy. Flow testing and strategic planning ensure hydrants deliver enough water when needed most.

Note: Hydrant presence alone does not guarantee sufficient flow. Regular testing and planning are essential for reliable fire protection.

Fire Hydrant Maintenance and Testing

Regular maintenance keeps fire hydrants ready for emergencies. According to national fire safety standards, hydrants must be inspected annually and after each use. Flow testing and maintenance occur every year, with comprehensive testing every five years. The table below outlines recommended maintenance actions:

| Maintenance Interval | Recommended Actions | Purpose/Notes |

|---|---|---|

| Annual (Every Year) | Inspect mechanical and structural components; perform flow testing | Ensures reliability and compliance with NFPA regulations |

| After Each Use | Inspect for leaks, loose bolts, debris obstruction | Addresses strain and wear from operation |

| Every Five Years | Comprehensive testing, valve analysis, lubrication, pressure testing | Deep inspection; addresses aging infrastructure |

| As Needed (Damage) | Immediate inspection and repair if damage is detected | Prevents failure during emergencies |

Common issues found during testing include corrosion, leaks, valve malfunctions, and obstructions. Crews address these problems through cleaning, lubrication, repairs, and part replacement. Regular maintenance extends the lifespan of fire hydrants and ensures they function properly during emergencies.

Reminder: Reliable and accessible hydrants, maintained by companies like Yuyao World Fire Fighting Equipment Factory, are critical for community safety and effective firefighting.

Fire Hydrant systems play a vital role in urban firefighting.

- They provide fast, reliable water for controlling fires and preventing spread.

- Internal and external hydrants support firefighting on all levels.

- Automatic and integrated systems improve response.

Recent data shows that well-maintained hydrants reduce property loss and save lives.

FAQ

How often should fire hydrants undergo inspection?

Fire departments inspect hydrants at least once a year. Regular checks help ensure each hydrant works properly during emergencies.

What causes low water pressure in fire hydrants?

Old pipes, closed valves, or debris can lower water pressure. Firefighters report these issues so city crews can fix them quickly.

Can anyone use a fire hydrant?

Only trained firefighters or authorized personnel may use hydrants. Unauthorized use can damage equipment or reduce water supply for emergencies.

Post time: Jul-20-2025