The Pressure reducing valve E Type keeps fire hydrant systems safe by controlling water pressure. They help prevent over-pressurization, so the system works when needed. Water Pressure Reducing Valve, Motorized Pressure Reducing Valve, and Mechanical Pressure Reducing Valve all support compliance with fire safety standards through regular checks and maintenance.

Pressure Reducing Valve E Type: Compliance Functions

Purpose and Operation

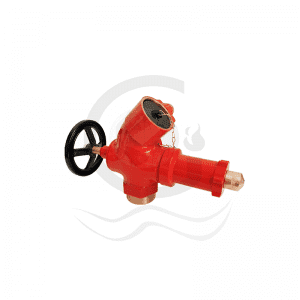

The Pressure reducing valve E Type plays a big role in fire protection systems. It keeps water pressure at a safe level, so pipes and hoses do not burst during emergencies. This valve works by adjusting the flow from the main water supply. When the inlet pressure changes, the valve automatically opens or closes to keep the outlet pressure steady. Firefighters can count on a reliable stream of water, even if the pressure in the system goes up or down. The valve’s strong brass body can handle high pressure, up to 30 bar, and it fits easily into many types of fire hydrant systems. People often see these valves in places like hospitals, malls, and tall buildings. They help protect equipment from damage and make sure water is always ready when needed.

Key Features Supporting Fire Safety Standards

The Pressure reducing valve E Type comes with features that help meet strict fire safety rules. It is certified to BS 5041 Part 1 and ISO 9001:2015, showing it meets global safety standards. The valve can adjust outlet pressure between 5 and 8 bars, which is important for different building needs. Its design allows for quick installation and easy maintenance. The valve also supports a high flow rate, up to 1400 liters per minute, which helps firefighters control fires faster. In high-rise buildings, this valve lets engineers set the right pressure for each floor, making sure every hose gets enough water. These features help prevent system failures and keep people and property safe during a fire.

Pressure Reducing Valve and Fire Safety Standards

Relevant Codes and Standards (NFPA, IBC, BS 5041)

Fire safety codes set the rules for how buildings protect people and property from fire. The Pressure Reducing Valve E Type helps meet these rules by controlling water pressure in fire hydrant systems. Different countries and regions use their own standards, but many follow guidelines from groups like NFPA, IBC, and BS 5041.

Here’s a quick look at how these standards compare:

| Standard | Main Requirement | Special Notes |

|---|---|---|

| NFPA 20 | PRVs needed on diesel pumps if pressure exceeds ratings | Electric pumps need PRVs only with variable speed drivers |

| NFPA 13 & 14 | Pressure control valves must keep hose connections below 175 psi | Separate valves for different hose classes allowed |

| BS 5041 | Valves must pass water flow and pressure tests | Focuses on valve construction and durability |

| IBC | Follows NFPA and local codes for fire protection | Adapts to building height and system design |

Tip: International standards may set different pressure limits and installation rules, but they all want safe, reliable fire protection.

Fire safety standards keep changing as new technologies appear. For example, NFPA 20 now uses variable speed pumps and higher pressure-rated parts instead of relying only on pressure reducing valves. Singapore’s rules now ask for smart PRVs that can connect to building management systems and use real-time diagnostics.

How Pressure Reducing Valve E Type Meets Compliance Requirements

The Pressure Reducing Valve E Type matches the strict demands of these standards. It controls water pressure so that pipes and hoses do not burst or leak. The valve’s design lets it adjust outlet pressure between 5 and 8 bars, which fits the needs of many buildings. Its strong brass body and high-quality casting help it pass tough water flow and pressure tests, just like BS 5041 requires.

- The valve keeps water pressure steady, even when the supply changes.

- It supports high flow rates, so firefighters get enough water fast.

- The valve’s manual control and protective cap make it easy to use and maintain.

- It resists corrosion, which means it works well for years.

The Pressure Reducing Valve E Type also fits into systems that follow NFPA 13 and NFPA 14. These codes set maximum pressures for hose connections and require pressure regulating devices when those limits are passed. The valve’s ability to handle high inlet pressures and reduce them safely helps buildings stay within these limits.

Preventing System Failures and Ensuring Reliable Performance

Fire hydrant systems must work every time there is an emergency. The Pressure Reducing Valve E Type helps prevent common problems that can stop a system from working.

- Regular maintenance keeps the valve working smoothly.

- The brass body resists rust and corrosion, so the valve does not get stuck.

- Good sealants stop leaks and keep water pressure strong.

- Smart design avoids water hammer, which can damage pipes.

The valve’s streamlined body lets water flow easily, and its automatic adjustment keeps pressure steady. Firefighters can trust that the system will deliver water when they need it most. The valve’s high-quality materials and careful manufacturing mean it will last a long time and keep protecting people and property.

Note: Reliable pressure regulation protects firefighting equipment and helps sprinklers activate quickly, stopping fires before they spread.

The Pressure Reducing Valve E Type stands out because it meets international safety standards, uses durable materials, and offers easy manual control. These features make it a key part of any fire hydrant system, helping buildings stay safe and compliant with fire safety codes.

Inspection and Maintenance of Pressure Reducing Valve E Type

Inspection Procedures for Compliance

Regular inspections help keep the Pressure reducing valve working safely and reliably. During inspections, technicians look for leaks, cracks, and signs of wear in the pilot system and main valve. They also check for dirt or blockages in strainers and filters. Removing air from the pilot system prevents false readings. Inspectors test diaphragms for leaks and make sure all handles and fittings are in place. These steps help spot problems like broken valves, blocked orifices, or worn seats before they cause bigger issues.

Tip: Cleaning strainers and checking for dirt on valve parts can prevent pressure spikes and system failures.

Testing and Performance Verification

Testing shows if the valve performs as it should. According to NFPA guidelines, two main tests keep the valve in top shape:

| Test Type | Frequency | Description |

|---|---|---|

| Full Flow Test | Every 5 years | Measures pressure at highest flow; checks if valve reduces pressure correctly. |

| Partial Flow Test | Annually | Opens valve slightly to keep it moving and working; ensures it does not stick. |

During these tests, technicians measure upstream and downstream pressures, flow rates, and valve position. They look at how well the valve controls pressure peaks and keeps the target pressure steady.

Maintenance Best Practices

Good maintenance keeps the valve reliable and extends its life. Here are some best practices:

- Schedule maintenance based on the valve’s condition, not just the calendar.

- Lubricate moving parts to stop sticking.

- Use sensors to watch valve performance in real time.

- Store spare valves in clean, dry places.

- Cover valve openings to keep out dirt.

- Rotate stock to keep seals and lubricants fresh.

- Follow industry standards for every step.

These habits help the Pressure reducing valve stay compliant and ready for emergencies.

Regular inspection and maintenance keep fire hydrant systems safe and reliable.

- Quarterly checks catch problems early.

- Annual and five-year tests make sure valves work when needed.

Neglecting these steps can lead to system failure, legal trouble, and higher insurance costs. Stay proactive to protect people and property.

| Consequence | Impact |

|---|---|

| System Failure | Firefighting efforts may not succeed |

| Legal Trouble | Fines or penalties for code violations |

| Higher Insurance | Increased premiums or denied coverage |

FAQ

What does the Pressure Reducing Valve E Type do in a fire hydrant system?

The valve keeps water pressure safe and steady. It helps firefighters get the right amount of water during an emergency.

How often should someone inspect the Pressure Reducing Valve E Type?

Experts suggest checking the valve every three months. Regular inspections help catch problems early and keep the system ready.

Is the Pressure Reducing Valve E Type hard to install?

No, most installers find it easy to fit. The valve comes with clear instructions and standard connections for quick setup.

Tip: Always follow the manufacturer’s guide for best results.

Post time: Aug-15-2025