Fire Hose Reel&Cabinet systems are essential for industrial fire safety, providing tailored solutions for warehouses and factories to address specific layouts and hazards. These systems ensure quick access to Fire Hose and Fire Hose Reel, enabling an effective fire response. Constructed with robust, rust-resistant materials, Hose Reel Cabinet systems comply with strict fire safety standards, enhancing overall workplace safety.

Key Takeaways

- Special fire hose reels and cabinets improve safety. They handle fire risks in warehouses and factories and give fast access to fire tools.

- Keeping fire hose systems in good shape is important. Check for leaks and test them twice a year to stay ready for emergencies.

- Talking to fire safety experts helps businesses pick the best systems. Their advice follows rules and makes places safer.

Understanding Fire Hose Reel & Cabinet Systems

Definition and Purpose

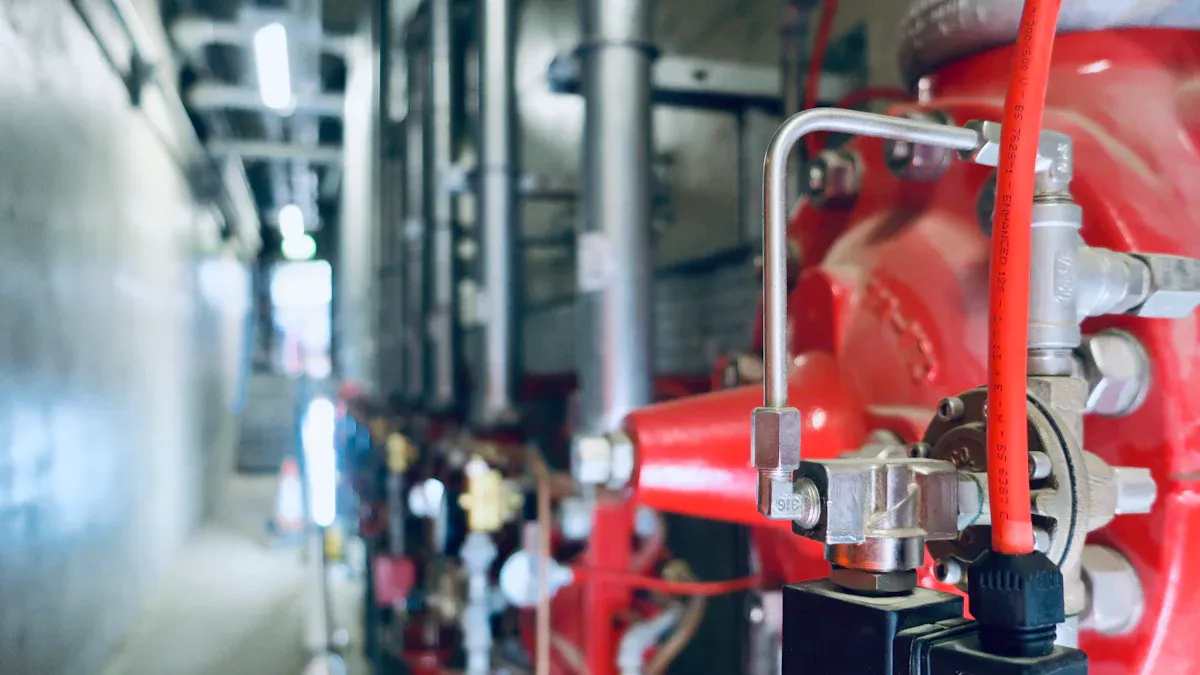

Fire Hose Reel & Cabinet systems play a vital role in industrial fire safety. These systems are integral to standpipe systems, providing building occupants with tools to combat fires during their early stages. Designed for ease of use, they allow individuals without firefighting expertise to respond effectively to small fires. By preventing flames from escalating, these systems serve as a critical first line of defense in fire safety.

Key Components

Fire Hose Reel & Cabinet systems consist of several essential components, each designed to ensure functionality and reliability. Key specifications include:

| Component | Specification |

|---|---|

| Capacity | Fire hose reel |

| Material | Carbon Steel |

| Cabinet Dimension | 800x700x160mm / 800x750x200mm |

| Surface | Red powder coating |

| Mounting | Wall surface |

| Hose Diameter | 9mm to 20mm |

| Hose Length | Up to 36 meters |

| Shut-Off Valve | Gate valve |

| Nozzle | Adaptable nozzles (brass) |

| Drum | Steel or plastic |

| Water Supply | Connected to internal water pipe network |

Regular maintenance ensures these components remain operational. Tasks include inspecting for leaks, testing nozzle functionality, and verifying water flow.

Types of Fire Hose Cabinets

Fire hose cabinets come in various designs to meet diverse industrial needs. Common types include:

| Fire Hose Cabinet | Description |

|---|---|

| Standard Cabinet | Accommodates different combinations of fire hose racks. |

| Hose Reel Cabinet | Features a single-door design for fixed or swinging hose reels. |

These cabinets are typically wall-mounted and constructed from durable materials like mild steel. They often feature epoxy powder red finishes for visibility and plat glass for easy inspection.

The Importance of Custom Solutions

Addressing Unique Industrial Challenges

Warehouses and factories often face distinct fire safety challenges due to their size, layout, and operational hazards. Standardized fire safety systems may not address these complexities effectively. Custom solutions for Fire Hose Reel & Cabinet systems ensure that fire safety measures align with the specific needs of each facility. For example, a petrochemical plant may require systems that resolve communication issues between fire safety components, while a manufacturing facility might need upgrades to eliminate false alarms.

The following table highlights real-world challenges and the tailored solutions implemented to address them:

| Sector | Challenge Description | Solution Description |

|---|---|---|

| Gas Turbine Safety | A major oil company required continuous protection for their gas turbines and personnel. | Implemented a rigorous fire protection system tailored to the plant’s needs. |

| Transit Fire Safety | A rapid transit system needed timely fire response capabilities. | Developed a real-time fire suppression system that met stringent certification standards. |

| Petrochemical Safety | Fire systems at a petrochemical plant had communication issues. | Enhanced safety with a compliant fire safety solution that resolved communication problems and reduced costs. |

| Manufacturing Safety | A chemical company faced issues with nuisance alarms and system faults. | Upgraded to a reliable fire system to eliminate false alarms and improve overall safety. |

Customizing fire safety systems ensures that these challenges are addressed effectively, enhancing safety and operational efficiency.

Examples of Customization Needs

Fire safety systems must adapt to the unique requirements of different industries and building types. Customization ensures that these systems provide optimal protection while meeting operational demands. Examples of specific customization needs include:

- High-rise buildings require systems that support phased evacuation, while industrial complexes may need customized fire detection strategies.

- Customizable data dashboards and audit reports are crucial for fire safety software, enabling tailored insights for building management.

- Fire alarm system designs must consider unique building layouts and specific fire safety needs, such as occupancy levels and structural complexities.

These examples demonstrate the importance of tailoring fire safety systems to the specific needs of each facility, ensuring comprehensive protection.

Compliance with Regulations

Custom solutions for Fire Hose Reel & Cabinet systems also play a critical role in ensuring compliance with fire safety regulations. Regulatory bodies mandate specific requirements for fire safety equipment to guarantee their effectiveness during emergencies. Key regulations include:

- The OSHA regulation 1910.158(c)(1) mandates that fire hose reels and cabinets must be designed for prompt use during emergencies.

- Employers must ensure that these reels and cabinets are clearly identified and used solely for fire equipment.

- Effective safety communication practices dictate that fire hose locations must be clearly marked to facilitate quick access in emergencies.

By adhering to these regulations, custom fire safety systems not only enhance safety but also help businesses avoid penalties and maintain operational continuity.

Features of Custom Fire Hose Reel & Cabinet Systems

Material and Durability

Custom Fire Hose Reel & Cabinet systems are designed with materials that prioritize strength and longevity. These systems often utilize carbon steel, stainless steel, or aluminum alloys, which provide excellent resistance to corrosion and wear. The choice of material depends on the environment where the system will be installed. For instance, facilities exposed to high humidity or chemical fumes benefit from stainless steel cabinets due to their superior anti-corrosion properties.

Durability also extends to the system’s surface finishes. Powder-coated surfaces enhance resistance to scratches and rust, ensuring the system remains functional and visually intact over time. Regular inspections and maintenance further contribute to the longevity of these systems, making them a reliable component of industrial fire safety infrastructure.

Accessibility and Design

Accessibility and design play a pivotal role in the effectiveness of Fire Hose Reel & Cabinet systems. These systems are engineered to ensure quick and easy access during emergencies. Features such as ergonomic handles, clear labeling, and strategically placed cabinets enhance usability. The design must also accommodate the specific layout of the facility, ensuring that fire safety equipment is within reach when needed most.

Innovative technologies have further improved accessibility. For example:

- Datacasting technology, tested in cities like Houston and Chicago, has enhanced communication for first responders. During the 2016 Houston floods, this technology transmitted real-time helicopter video, improving situational awareness.

- The WIFIRE Edge platform, developed with the University of California San Diego, integrates real-time data and predictive modeling to assist fire personnel in making informed decisions.

These advancements demonstrate how thoughtful design and technology integration can significantly improve emergency response effectiveness.

Integration with Fire Safety Standards

Custom Fire Hose Reel & Cabinet systems must align with established fire safety standards to ensure optimal performance during emergencies. Compliance with regulations such as OSHA 1910.158(c)(1) guarantees that these systems are designed for prompt and efficient use. Additionally, clear identification and proper installation of fire hose cabinets are essential for meeting safety communication requirements.

Integration with fire safety standards also involves compatibility with other fire protection systems. For example, these cabinets often connect seamlessly with sprinkler systems and fire alarms, creating a cohesive safety network. This ensures that all components work together to provide comprehensive protection, minimizing risks and enhancing overall safety in industrial environments.

Benefits of Custom Fire Hose Reel & Cabinet Systems

Enhanced Safety

Custom Fire Hose Reel & Cabinet systems improve safety by addressing the specific risks of industrial environments. Warehouses and factories often store flammable materials or operate heavy machinery, increasing fire hazards. Tailored systems ensure that fire safety equipment is strategically placed for quick access during emergencies. Features like durable construction and clear labeling enhance reliability, reducing the risk of equipment failure when seconds matter most. These systems act as a safeguard, protecting personnel and property from catastrophic damage.

Efficiency in Emergency Response

Emergency response efficiency depends on the accessibility and functionality of fire safety systems. Custom solutions optimize the placement of Fire Hose Reel & Cabinet systems, ensuring they align with the facility’s layout. Ergonomic designs and intuitive features allow workers to deploy fire hoses quickly, minimizing response time. Integrated technologies, such as real-time communication platforms, further enhance coordination during emergencies. These systems empower personnel to act decisively, preventing fires from escalating and ensuring a swift resolution.

Cost-Effectiveness

Custom fire safety systems offer measurable cost benefits over time. Evaluating the total cost of ownership reveals savings in maintenance, durability, and warranty coverage. High-quality materials reduce the need for frequent replacements, while robust designs minimize repair costs.

- Maintenance schedules become more predictable, lowering operational disruptions.

- Durable components extend the lifespan of the system, reducing long-term expenses.

- Warranty coverage provides additional financial protection, ensuring peace of mind for facility managers.

These factors contribute to the cost-effectiveness of custom solutions, making them a smart investment for industrial facilities.

Long-Term Compliance

Compliance with fire safety regulations requires systems that meet specific standards. Custom Fire Hose Reel & Cabinet systems ensure adherence to these requirements by incorporating features like clear identification and proper installation. Regulatory bodies, such as OSHA, mandate that fire safety equipment must be accessible and functional during emergencies. Custom solutions align with these guidelines, reducing the risk of penalties and ensuring operational continuity. By prioritizing compliance, businesses protect their workforce while maintaining their reputation in the industry.

Choosing the Right Fire Hose Reel & Cabinet System

Assessing Facility Needs

Every facility has unique fire safety requirements. Warehouses and factories differ in size, layout, and operational hazards. Conducting a thorough assessment helps identify the specific needs of the facility. Key factors include the type of materials stored, the presence of flammable substances, and the accessibility of fire safety equipment. For example, facilities handling chemicals may require corrosion-resistant cabinets, while high-traffic areas benefit from compact, wall-mounted designs. A detailed evaluation ensures that the selected system aligns with the facility’s operational demands and safety priorities.

Consulting Experts

Expert consultation plays a critical role in selecting the right fire hose reel and cabinet system. Industry guidelines, such as NFPA 1962, emphasize the importance of involving professionals during the selection process. Consulting local fire departments, corporate safety officers, and property insurance representatives ensures that the system meets safety standards and operational requirements. These experts provide valuable insights into compliance, maintenance, and system integration, helping businesses make informed decisions. Their expertise minimizes risks and enhances the overall effectiveness of fire safety measures.

Evaluating Customization Options

Customization ensures that fire safety systems address the unique challenges of each facility. Businesses should evaluate options such as material selection, cabinet dimensions, and hose reel configurations. For instance, stainless steel cabinets offer superior durability in humid environments, while powder-coated finishes enhance visibility. Customizable features like ergonomic handles and clear labeling improve usability. Facilities should also consider integrating advanced technologies, such as real-time reporting systems, to enhance emergency response capabilities. Tailored solutions maximize safety and operational efficiency.

Ensuring Regulatory Compliance

Regulatory compliance is essential for maintaining workplace safety and avoiding penalties. A systematic review process ensures that custom solutions meet fire safety standards. Key steps include:

- Verifying that fire safety records are accessible and up to date

- Checking the functionality of sprinkler systems

- Documenting hazards and scheduling follow-up inspections

- Providing training for staff to identify risks early

- Staying informed about updates to fire safety regulations

These measures ensure that fire hose reel and cabinet systems remain compliant, reliable, and effective during emergencies.

Fire hose reel and cabinet systems are indispensable for industrial safety. Their custom designs address unique challenges in warehouses and factories, ensuring rapid fire suppression and compliance with regulations.

| Benefit | Description |

|---|---|

| Rapid access and deployment | Enables quick fire suppression to prevent escalation of small fires. |

| Minimal training required | Staff can use the system effectively with little training. |

| Compact design | Takes up minimal space, making it suitable for various environments. |

| Fixed water supply | Ensures availability of water without relying on external sources. |

| Durable components | Requires little maintenance if regularly inspected. |

| Reassurance for owners | Provides peace of mind regarding fire safety measures. |

| Supports insurance requirements | Helps meet insurance standards for property protection. |

These systems find applications in diverse settings:

- Factories and warehouses

- Schools and universities

- Hospitals and aged care homes

Proactive evaluation and upgrades ensure these systems remain effective, safeguarding lives and property.

FAQ

What is the primary purpose of a fire hose reel and cabinet system?

The system provides quick access to fire suppression tools, enabling individuals to control small fires effectively before they escalate.

How often should fire hose reel and cabinet systems undergo maintenance?

Experts recommend inspecting these systems every six months to ensure functionality, compliance, and readiness during emergencies.

Can fire hose cabinets be customized for specific industrial needs?

Yes, manufacturers like Yuyao World Fire Fighting Equipment Factory offer tailored solutions to meet unique facility requirements, ensuring optimal safety and compliance.

Post time: May-09-2025