Fire Hydrant Valve standards play a crucial role in safeguarding lives and property by guaranteeing reliable performance during emergencies. Residential standards prioritize compact designs and easy accessibility, while industrial standards focus on durability and high-pressure efficiency. Adhering to these standards helps prevent operational failures and legal complications, ensuring preparedness in critical situations. Certified equipment, such as Fire Hose Reel&Cabinet systems and Fire Extinguisher Pillar Fire Hydrant setups, further strengthens overall safety measures.

Key Takeaways

- Fire hydrant valve rules make sure they work well in emergencies.

- Checking and fixing them often helps them stay ready and safe.

- Picking approved tools from good brands, like Yuyao World Fire Fighting Equipment Factory, keeps people safe and follows the rules.

Overview of Fire Hydrant Valve Standards

Definition and Purpose of Fire Hydrant Valve Standards

Fire hydrant valve standards establish guidelines to ensure the reliability and efficiency of fire hydrants during emergencies. These standards focus on critical aspects such as design, materials, and testing procedures. Organizations like the American Water Works Association (AWWA) and the National Fire Protection Association (NFPA) provide authoritative definitions that highlight their importance:

- The AWWA C502 standard specifies minimum requirements for dry-barrel fire hydrants, emphasizing durability and performance under varying conditions.

- The AWWA C503 standard outlines requirements for wet-barrel fire hydrants, addressing inspection, testing, and shipping protocols.

- The NFPA underscores the significance of regular fire hydrant testing to ensure dependable water sources during emergencies.

By adhering to these standards, manufacturers and users can guarantee that fire hydrant valves meet safety expectations and perform effectively when needed.

Importance of Compliance for Fire Safety

Compliance with fire hydrant valve standards plays a vital role in protecting lives and property. It ensures that hydrants function correctly under pressure and deliver adequate water flow during firefighting operations. Legal codes, such as Section 507.5 of the Fire Code, mandate that private fire hydrant systems meet specific requirements to maintain operational readiness.

| Section | Description |

|---|---|

| 507.5 | Private fire hydrant systems shall comply with the requirements of FC 507.5.1 through 507.5.6. |

Regular inspections and maintenance practices further enhance compliance, reducing the risk of equipment failure during emergencies. Trusted manufacturers like Yuyao World Fire Fighting Equipment Factory provide certified fire hydrant valves that align with these standards, ensuring reliability and safety in both residential and industrial settings.

Residential Fire Hydrant Valve Standards

Common Regulations for Residential Fire Hydrant Valves

Residential fire hydrant valves must meet specific regulatory frameworks to ensure safety and functionality during emergencies. These regulations address placement, water supply, and maintenance requirements. The Building Regulations 2010 (Part B: Fire Safety) outlines essential measures, including the strategic placement of hydrants to maximize accessibility. British Standard BS 9990:2015 provides detailed specifications for the design, installation, and upkeep of fire hydrants, ensuring their reliability under various conditions.

For residential buildings exceeding four stories or containing more than 50 dwellings, additional hydrants are mandated to guarantee sufficient water supply for firefighting operations. These guidelines aim to prevent operational failures and enhance preparedness during critical situations.

| Standard | Description |

|---|---|

| NFPA 11 | Standard for Low-, Medium-, and High-Expansion Foam |

| NFPA 13 | Standard for the Installation of Sprinkler Systems |

| NFPA 13D | Standard for the Installation of Sprinkler Systems in One- and Two-Family Dwellings |

| NFPA 13R | Standard for the Installation of Sprinkler Systems in Residential Occupancies up to Four Stories in Height |

| NFPA 14 | Standard for the Installation of Standpipe and Hose Systems |

| NFPA 15 | Standard for Water Spray Fixed Systems for Fire Protection |

| NFPA 20 | Standard for the Installation of Stationary Pumps for Fire Protection |

| NFPA 22 | Standard for Water Tanks for Private Fire Protection |

| NFPA 24 | Standard for the Installation of Private Fire Service Mains and Their Appurtenances |

| NFPA 30 | Flammable and Combustible Liquids Code |

| NFPA 30B | Code for the Manufacture and Storage of Aerosol Products |

These standards collectively ensure that residential fire hydrant valves meet the necessary safety and operational benchmarks.

Challenges in Meeting Residential Compliance Standards

Residential compliance with fire hydrant valve standards often encounters obstacles due to aging infrastructure and environmental factors. Older pipes frequently fail, requiring replacement to maintain system integrity. Pipe material also plays a significant role, as certain materials exhibit higher failure rates under pressure. Soil conditions further impact compliance, with specific types of soil accelerating pipe degradation.

Statistical trends highlight common areas where compliance issues arise:

| Factor | Description |

|---|---|

| Pipe Age | Older pipes are more prone to failures, indicating a need for replacement. |

| Pipe Material | Different materials have varying failure rates, affecting compliance. |

| Soil Conditions | Soil type can influence pipe integrity and failure rates. |

| Number of Breaks | A higher number of breaks indicates potential compliance issues. |

| Rehabilitation History | Previous repairs can affect the likelihood of future failures. |

| Pressure of Operation | High operational pressure can lead to increased failure rates. |

| Water Quality Complaints | Complaints about taste, odor, or color can indicate underlying compliance issues. |

| Seasonal Failures | Failures in northern climates often occur during temperature changes, indicating environmental impacts on compliance. |

To address these challenges, regular inspections and proactive maintenance are essential. Collaborating with trusted manufacturers like Yuyao World Fire Fighting Equipment Factory ensures access to certified fire hydrant valves that meet residential standards. Their expertise in producing reliable equipment helps homeowners and property managers overcome compliance hurdles effectively.

Industrial Fire Hydrant Valve Standards

Key Differences Between Residential and Industrial Fire Hydrant Valves

Industrial fire hydrant valves differ significantly from residential ones due to their specialized design and operational requirements. Residential valves prioritize accessibility and compactness. Industrial valves focus on durability, high-pressure tolerance, and compatibility with large-scale firefighting systems.

Industrial valves often feature robust materials like ductile iron or stainless steel to withstand extreme conditions. Their larger size accommodates higher water flow rates, essential for combating large-scale fires. Residential valves, on the other hand, are smaller and designed for lower pressure systems.

| Feature | Residential Valves | Industrial Valves |

|---|---|---|

| Material | Lightweight alloys | Heavy-duty metals |

| Size | Compact | Larger dimensions |

| Pressure Tolerance | Lower pressure | High-pressure systems |

| Application | Small-scale emergencies | Large-scale firefighting operations |

Industrial valves also integrate advanced features like pressure regulation and corrosion resistance. These enhancements ensure reliability in demanding environments, such as factories, warehouses, and chemical plants.

Examples of Industrial Applications and Requirements

Industrial fire hydrant valves serve critical roles in environments with high fire risks. Factories handling flammable materials require valves capable of delivering consistent water flow under extreme pressure. Warehouses storing combustible goods rely on valves designed to operate efficiently during prolonged firefighting efforts.

Chemical plants demand specialized valves resistant to corrosive substances. These valves must meet stringent standards, such as those outlined by the NFPA and AWWA, to ensure operational safety. For example, NFPA 24 specifies requirements for private fire service mains, which include industrial hydrant systems.

Tip: Industrial facilities should conduct regular inspections to verify compliance with fire hydrant valve standards. Collaborating with trusted manufacturers like Yuyao World Fire Fighting Equipment Factory ensures access to certified valves tailored to industrial needs.

Industrial applications also require valves compatible with auxiliary firefighting equipment, such as foam systems and high-capacity pumps. These systems enhance firefighting efficiency, especially in environments with unique hazards.

By adhering to industrial standards, facilities can minimize fire risks and ensure operational readiness. Reliable fire hydrant valves play a pivotal role in safeguarding lives and property in these high-stakes environments.

Ensuring Compliance with Fire Hydrant Valve Standards

Regular Inspections and Maintenance Practices

Regular inspections and maintenance ensure fire hydrant valves remain operational during emergencies. NFPA 291 recommends annual inspections to verify accessibility and functionality. Flow tests, conducted every five years, assess water pressure and flow rates. Maintenance logs play a critical role in tracking system performance. These logs should include inspection dates, operational status, repairs performed, and technician credentials.

| Aspect | Details |

|---|---|

| Compliance Standard | NFPA 291 |

| Recommended Inspection | Annual inspections for fire hydrant valves |

| Flow Test Frequency | Every five years |

| Key Maintenance Log Details | - Inspection Dates: Record date and time of each inspection |

| - Operational Status: Note functionality of the hydrant | |

| - Repairs Performed: Document types of repairs completed | |

| - Flow Test Results: Include pressure readings and flow rates | |

| - Technician Information: Log name and credentials of personnel | |

| Tools for Record-Keeping | Modern tools like GIS-integrated software for efficient management |

Additional practices include proper lubrication to prevent corrosion, flushing to remove debris, and leak checks to identify joint issues. Accessibility inspections ensure hydrants remain unobstructed, while height checks confirm proper placement for emergency use. These measures collectively enhance compliance and operational readiness.

Tip: Investing in regular inspections reduces maintenance costs and ensures hydrants perform effectively during emergencies.

Working with Certified Professionals and Trusted Manufacturers

Certified professionals play a vital role in maintaining fire hydrant valve compliance. Their expertise ensures accurate assessments and adherence to industry standards. Regular testing by certified experts enhances firefighting capabilities and emergency preparedness.

| Benefit | Description |

|---|---|

| Cost Savings | Helps utilities save money on replacement of hydrants. |

| Improved Water Quality | Enhances water quality through unidirectional flushing (UDF). |

| Compliance | Assists in maintaining compliance with safety standards. |

Professionals also help facilities meet local and state codes, lowering insurance premiums and providing peace of mind. Collaborating with trusted manufacturers ensures access to high-quality valves designed for specific system needs.

- Lower insurance premiums.

- Meet local/state code compliance.

- Peace of mind that hydrants work when needed.

Role of Yuyao World Fire Fighting Equipment Factory in Compliance Solutions

Yuyao World Fire Fighting Equipment Factory offers reliable solutions for fire hydrant valve compliance. Their valves meet industry standards, including NFPA 14, ensuring safety in diverse applications. The factory specializes in producing high-quality valves tailored to residential and industrial needs.

Their products undergo rigorous testing to validate flow rates, pressure levels, and regulatory compliance. These valves enhance firefighting preparedness by delivering consistent water flow during emergencies. Engineers rely on design data provided by the factory to create efficient water systems.

| Metric | Description |

|---|---|

| Firefighting Preparedness | Ensures adequate water flow and pressure for effective firefighting operations. |

| Design Information | Provides essential data for engineers to design efficient water systems based on flow rates and pressure levels. |

| Confirming Flow Rates | Validates that designed flows are met in existing systems through real-world data. |

| Regulatory Compliance | Ensures adherence to standards and insurance requirements through periodic flow testing. |

| Emergency Response Planning | Identifies areas with insufficient water supply for better resource allocation during emergencies. |

Yuyao World Fire Fighting Equipment Factory’s commitment to compliance and quality makes them a trusted partner in fire safety solutions.

Understanding fire hydrant valve standards ensures safety and operational efficiency across residential and industrial settings. Adherence to these standards significantly reduces risks, as demonstrated by the low fatality rate in hospital fires due to strict compliance.

| Safety Outcome | Data |

|---|---|

| Annual hospital fires in the US | Approximately 1,100 |

| Annual fatalities in hospital fires | Less than 1 death per year |

| Reason for safety record | Strict adherence to fire codes and standards |

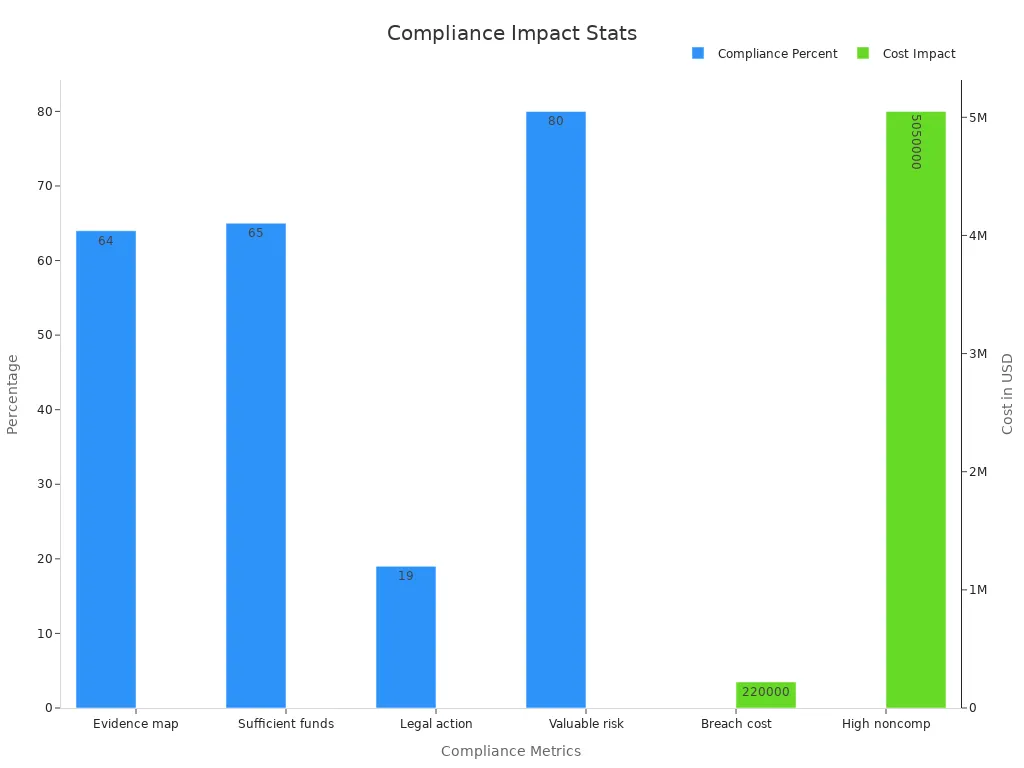

Compliance also minimizes legal issues and enhances readiness. Organizations with strong compliance practices report fewer regulatory actions and lower breach costs.

By prioritizing compliance, individuals and businesses safeguard lives, reduce financial risks, and maintain operational preparedness during emergencies.

FAQ

What are the key benefits of adhering to fire hydrant valve standards?

Compliance ensures operational readiness, reduces fire risks, and meets legal requirements. It also enhances safety for residential and industrial properties during emergencies.

How often should fire hydrant valves undergo inspections?

NFPA 291 recommends annual inspections for accessibility and functionality. Flow tests should occur every five years to verify water pressure and flow rates.

Why choose Yuyao World Fire Fighting Equipment Factory for fire hydrant valves?

Their products meet industry standards, ensuring reliability and safety. Rigorous testing validates performance, making them a trusted partner for compliance solutions.

Tip: Regular maintenance and certified equipment improve firefighting efficiency and reduce long-term costs.

Post time: May-13-2025