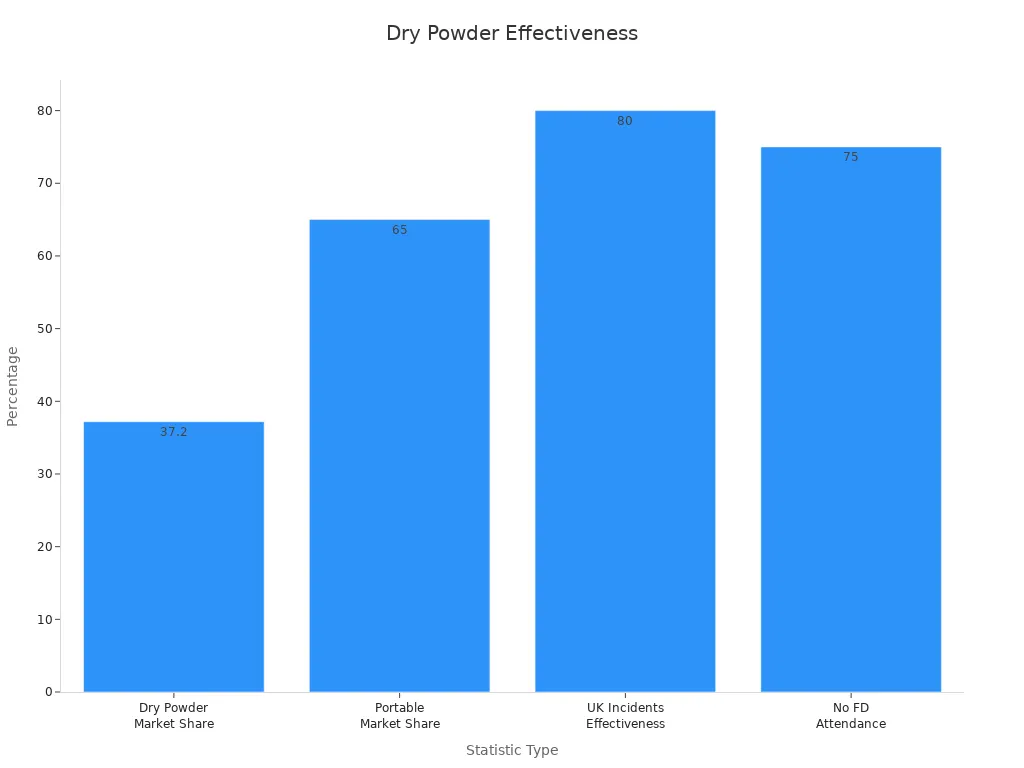

A dry powder fire extinguisher quickly interrupts the chemical chain reaction of fires. It handles Class B, C, and D fires, which include flammable liquids, gases, and metals. The market share reached 37.2% in 2022, highlighting its effectiveness in industrial settings, fire extinguisher cabinet installations, and alongside CO2 fire extinguisher or mobile foam fire extinguisher trolley systems.

Selecting the right extinguisher, such as a dry powder or fire extinguisherpillar fire hydrant, ensures safety for each fire risk.

Key Takeaways

- Dry powder fire extinguishers stop fires by interrupting the chemical reaction and work well on flammable liquids, electrical fires, and combustible metals.

- These extinguishers are safe for electrical fires, versatile for many fire types, and perform reliably even outdoors or in windy conditions.

- Always check the extinguisher’s label to match the fire class, maintain it regularly, and use it carefully to ensure safety and effectiveness.

Dry Powder Fire Extinguisher Definition and Identification

What Is a Dry Powder Fire Extinguisher

A dry powder fire extinguisher uses a specialized powder to stop fires by interrupting the chemical reaction that fuels them. Industry experts define this extinguisher as a device designed to control or extinguish fires involving flammable liquids, gases, and metals. The powder inside is non-conductive, making it safe for use on electrical fires. Class D fire extinguishers, a type of dry powder extinguisher, contain agents effective for combustible metal fires such as magnesium or lithium. These extinguishers do not have a numerical rating but display a ‘D’ symbol to show their specialization. Certifications like UL, CE, and BSI confirm that the extinguisher meets strict safety and performance standards. The ANSI/NFPA 17 standard also guides the design and reliability of dry chemical extinguishing systems. Yuyao World Fire Fighting Equipment Factory produces dry powder fire extinguishers that comply with these international standards, ensuring quality and safety for users.

How to Identify a Dry Powder Fire Extinguisher

Identifying a dry powder fire extinguisher is straightforward when following regulatory guidelines. Most models feature a red body with a blue panel above the operating instructions. This color coding matches British Standards and helps users quickly recognize the extinguisher type. The following table summarizes key identification features:

| Extinguisher Type | Color Coding | Identification Features | Fire Classes |

|---|---|---|---|

| Dry Powder | Red with blue panel | Blue label above instructions | A, B, C, Electrical |

Dry powder extinguishers work well in environments where water or foam could cause damage, such as storerooms with valuable archives. They remain effective even at low temperatures. Regular inspection and maintenance, as recommended by manufacturers like Yuyao World Fire Fighting Equipment Factory, ensure the extinguisher will perform reliably in an emergency.

Dry Powder Fire Extinguisher: Types of Fires and Fire Classes

Fire Classes Overview (A, B, C, D, Electrical)

Fire safety experts group fires into different classes based on the fuel source. Each class requires a specific approach for safe and effective extinguishing. The main fire classes include:

- Class A: Fires involving common combustibles such as wood, paper, fabric, trash, and light plastics. These fires often occur in offices, schools, and homes.

- Class B: Fires fueled by flammable liquids and gases like gasoline, paint, kerosene, propane, and butane. Industrial and storage areas face higher risks of these fires.

- Class C: Electrical fires start in equipment, wiring, or appliances. Data centers, construction sites, and facilities with heavy electrical use often encounter these hazards.

- Class D: Combustible metals such as magnesium, titanium, aluminum, and potassium can ignite in laboratories and factories. These fires require special handling.

- Class K: Cooking oils, greases, and fats burn in commercial kitchens and food service environments. Wet chemical extinguishers work best for these fires.

Fire extinguisher ratings use codes like 1A:10B:C to show which fire classes the device can handle. This system helps users match the extinguisher to the fire risk.

The table below summarizes the fire classes, typical fuel sources, and recommended suppression methods:

| Fire Class | Fuel Type / Typical Environment | Recommended Suppression Method | Fire Extinguisher Type |

|---|---|---|---|

| Class A | Wood, paper, fabric, trash, light plastics | Water, monoammonium phosphate | ABC powder, water, water mist, foam |

| Class B | Gasoline, paint, kerosene, propane, butane | Foam, CO2, remove oxygen | ABC powder, CO2, water mist, clean agent |

| Class C | Electrical equipment, wiring, data centers | Non-conductive agents | ABC powder, CO2, water mist, clean agent |

| Class D | Titanium, aluminum, magnesium, potassium | Dry powder agents only | Powder extinguishers for metal fires |

| Class K | Cooking oils, greases, fats | Wet chemical, water mist | Wet chemical, water mist |

Fire Classes Suitable for Dry Powder Fire Extinguisher

A Dry Powder Fire Extinguisher works best on several fire classes. It interrupts the chemical reaction that keeps the fire burning. This extinguisher type handles:

- Class B fires: Flammable liquids and gases. The powder smothers the fire and removes oxygen.

- Class C fires: Electrical fires. The powder is non-conductive, so it does not cause electric shock.

- Class D fires: Combustible metals. Specialized dry powder agents absorb heat and form a barrier between the metal and air.

Some models also carry an “ABC” rating, which means they can tackle Class A fires as well. However, water or foam extinguishers often work better for Class A fires. Dry powder extinguishers do not suit Class K fires, which involve cooking oils and fats.

Yuyao World Fire Fighting Equipment Factory produces dry powder fire extinguishers that meet international standards. Their products offer reliable performance for industrial, commercial, and laboratory settings. The company designs extinguishers for a wide range of fire risks, ensuring users have the right tool for each fire class.

Tip: Always check the label and fire class symbols on the extinguisher before use. This step ensures the device matches the fire risk.

Table: Dry Powder Fire Extinguisher Suitability by Fire Class

The following table shows which fire classes a Dry Powder Fire Extinguisher can handle:

| Fire Class | Suitable for Dry Powder Fire Extinguisher? | Notes |

|---|---|---|

| Class A | ⚠️ Sometimes (ABC models only) | Not ideal; use only if labeled “ABC” |

| Class B | ✅ Yes | Effective for flammable liquids/gases |

| Class C | ✅ Yes | Safe for electrical fires |

| Class D | ✅ Yes (specialized models) | Use only metal-specific powder |

| Class K | ❌ No | Not suitable for cooking oil/fat fires |

Note: Always select the correct extinguisher for the fire class. Using the wrong type can make the fire worse or cause injury.

Dry Powder Fire Extinguisher: How It Works, Advantages, and Limitations

How Dry Powder Fire Extinguishers Work

A Dry Powder Fire Extinguisher uses a pressurized gas, such as nitrogen or carbon dioxide, to expel powder from a steel canister. When someone presses the handle, a valve opens and the gas pushes the powder through a nozzle. The nozzle often has a flexible tip, which helps direct the powder at the base of the fire. This design allows the extinguisher to smother flames, absorb heat, and interrupt the chemical reaction that keeps the fire burning. The powder covers the fuel, cutting off oxygen and stopping the fire triangle. For metal fires, the powder forms a barrier that prevents the metal from reacting with air.

| Dry Powder Type | Chemical Nature | Fire Classes Suitable For | Mechanism of Action |

|---|---|---|---|

| Sodium Bicarbonate | Sodium bicarbonate with additives | Flammable liquids, gases, electrical equipment | Interrupts flame, non-toxic, high resistivity |

| Potassium Bicarbonate | Similar to sodium bicarbonate | Flammable liquids, gases, electrical equipment | Effective flame interruption and smothering |

| Monoammonium Phosphate | More effective on combustibles | Flammable liquids, gases, ordinary combustibles, electrical equipment | Smothers and chemically interrupts fire; corrosive to electronics |

Advantages of Dry Powder Fire Extinguishers

- These extinguishers work on several fire classes, including A, B, C, and D, making them versatile.

- They knock down flames quickly by creating a dense powder cloud that interrupts the fire’s chemical reaction and prevents re-ignition.

- Their simple mechanical design makes them reliable and cost-effective.

- They perform well outdoors and in windy conditions because the powder does not blow away easily.

- The powder is non-conductive, so it is safe for electrical fires.

- Specialized powders can handle metal fires, which other extinguishers cannot.

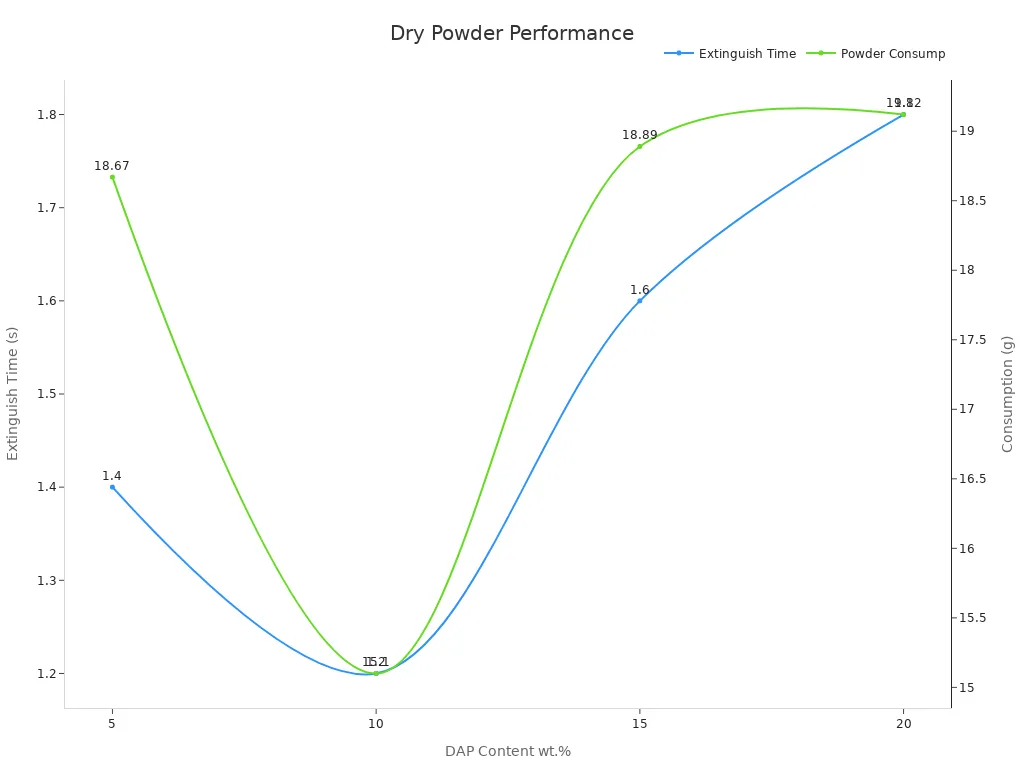

- Studies show that superfine powders reduce extinguishing time and powder use, while also lowering toxic gas emissions.

Tip: Dry powder extinguishers can suppress embers and deep-seated fires, reducing the risk of the fire starting again.

Limitations and Safety Considerations

- Powder can reduce visibility indoors and may damage sensitive equipment.

- Use the correct powder type for each fire class. Using the wrong type can be dangerous or ineffective.

- Do not use on fires that are too large or out of control. Evacuate if the extinguisher does not work.

- Always aim at the base of the fire, not the flames.

- After use, have the extinguisher checked by a professional.

- Regular maintenance and monthly inspections keep the extinguisher ready for emergencies.

- Powder residue requires careful clean-up, especially around electronics.

Note: Proper training and regular servicing are essential for safe and effective use of any fire extinguisher.

Dry powder extinguishers deliver fast, reliable fire suppression for Class A, B, C, and D fires. The HM/DAP powder achieves the shortest extinguishing time and lowest powder use, as shown below:

| Powder Type | Time (s) | Consumption (g) |

|---|---|---|

| HM/DAP | 1.2 | 15.10 |

- Always check labels and fire class symbols before use.

- Maintain monthly checks and annual servicing.

- Use in open areas, not enclosed spaces, to avoid powder inhalation.

FAQ

What should someone do after using a dry powder fire extinguisher?

They should have a professional inspect and recharge the extinguisher. Powder residue must be cleaned up, especially around electronics.

Can a dry powder fire extinguisher be used on kitchen fires?

Dry powder extinguishers do not suit kitchen fires involving cooking oils or fats. Wet chemical extinguishers work best for Class K fires.

How often should dry powder fire extinguishers be serviced?

Experts recommend monthly visual checks and annual professional servicing. Regular maintenance ensures the extinguisher works during emergencies.

Post time: Jul-03-2025