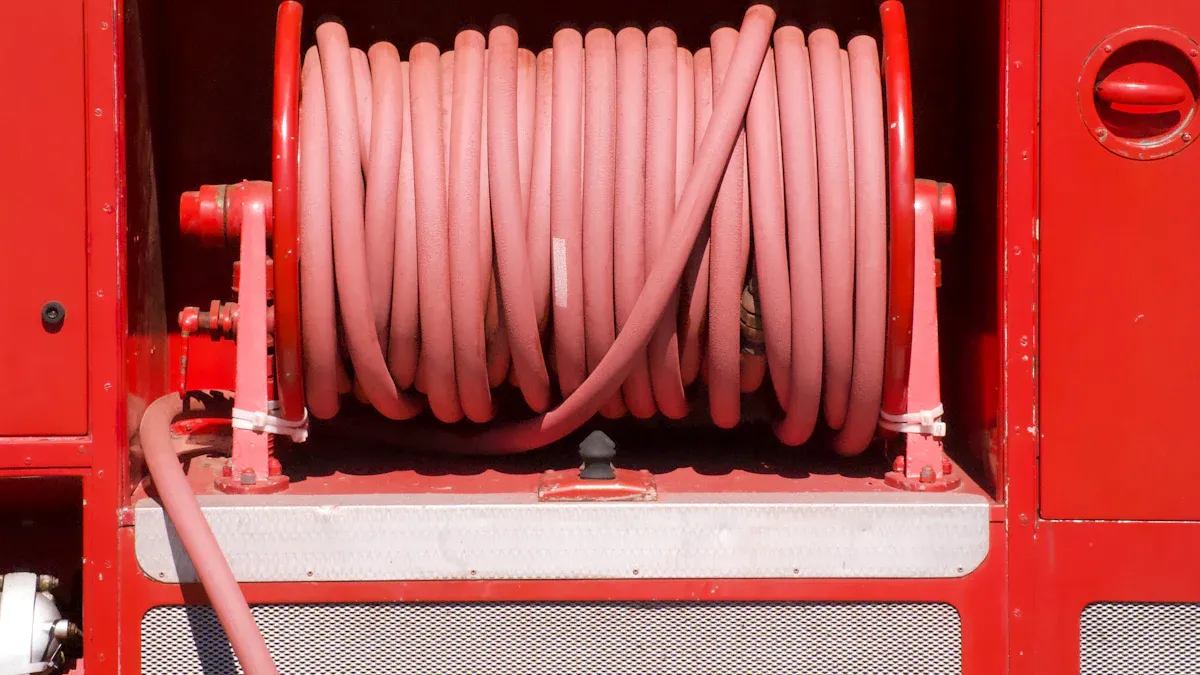

I find that a Rubber Fire Hose Reel offers easy maintenance with just a bit of routine care. I can handle most tasks without special skills. Unlike a Metal Fire Hose Reel, the Rubber Fire Hose Reel resists corrosion. I have also used a Retractable Fire Hose Reel and a Swing Arm Fire Hose Reel with similar results.

Rubber Fire Hose Reel Maintenance Tasks

Regular Inspections

I always start my maintenance routine with regular inspections. I check my Rubber Fire Hose Reel visually for any signs of damage or wear. I look for cracks, fraying, kinks, bulges, or any material degradation. I know that missing these signs can lead to hose failure when I need it most. I make sure to unroll the hose completely and inspect the fittings and valves. I also test the nozzle and ensure all connections are secure. I keep a record of each inspection, which helps me track the condition of my equipment over time.

Tip: I follow local regulations and building codes for inspection frequency. I usually inspect my hose reel at least once a year, but I check more often if my environment demands it.

Cleaning the Hose and Reel

Keeping my Rubber Fire Hose Reel clean is essential for its longevity. I disconnect and depressurize the hose before cleaning. I lay it flat on a clean surface and use a soft or medium bristle brush to remove dirt and debris. I avoid harsh chemicals because they can degrade the rubber. If the hose has been exposed to hazardous substances, I use approved decontamination methods. I rinse the hose with low-pressure water and dry it with a towel or let it air dry in a shaded area. I always store the hose in a cool, dry place away from direct sunlight and extreme temperatures.

Monthly Cleaning Checklist:

- Unroll and stretch the hose to remove kinks.

- Brush off dirt gently on all sides.

- Wash with mild soap and water if needed.

- Dry thoroughly before storage.

- Store loosely coiled or hung on the reel.

Checking for Leaks and Wear

I check for leaks and wear during every inspection. I pinch the hose liner to detect any separation or delamination. I examine the couplings for damaged threads, corrosion, or loose collars. I perform a pressure test by running water through the hose and maintaining the recommended pressure for a few minutes. If I see any leaks, bulges, or bursts, I remove the hose from service immediately. I pay special attention to areas near the fittings and any spots that look worn or abraded.

Note: Abrasion, kinking, crush damage, and thermal damage are common signs that my hose may need replacement.

Lubricating Moving Parts

I keep the moving parts of my Rubber Fire Hose Reel in top condition by lubricating them regularly. I inspect the reel weekly for wear and clean it as needed. I apply lubricant to the moving parts every month to ensure smooth operation. I use only lubricants recommended by the manufacturer to avoid damaging the reel. Once a year, I perform a thorough inspection and replace any worn components.

- Weekly: Inspect and clean the reel.

- Monthly: Lubricate moving parts.

- Annually: Replace worn components after a detailed inspection.

By following these maintenance tasks, I keep my Rubber Fire Hose Reel reliable and ready for use in any emergency.

Rubber Fire Hose Reel Maintenance Frequency

Home Use Schedule

I always set a regular schedule for checking my Rubber Fire Hose Reel at home. I know that fire safety equipment needs attention, even if I rarely use it. I inspect my hose reel at least once every six months. I look for cracks, leaks, or any signs of aging. I also make sure the hose is stored in a dry, well-ventilated area. I avoid direct sunlight and humidity because these can shorten the hose’s lifespan.

I never use a hose that looks worn or damaged. I replace my fire hose if it shows any signs of deterioration. I also keep in mind that a fire hose should not be used beyond eight years, even if it appears in good condition. This routine helps me feel confident that my equipment will work when I need it most.

Tip: I keep a simple logbook to record each inspection and cleaning. This habit helps me track the condition of my hose reel over time.

Industrial Use Schedule

In industrial settings, I follow a stricter maintenance schedule. I check the Rubber Fire Hose Reel every month. I work in environments where dust, chemicals, and heavy use can wear out equipment faster. I inspect the hose, nozzle, and fittings for any damage or leaks. I also test the reel mechanism to make sure it operates smoothly.

I clean the hose and reel after every use. I use only approved cleaning agents to avoid damaging the rubber. I also schedule a full professional inspection once a year. During this inspection, I check the pressure, replace worn parts, and make sure the reel meets all safety standards.

| Task | Home Use | Industrial Use |

|---|---|---|

| Visual Inspection | Every 6 months | Every month |

| Cleaning | Every 6 months | After each use |

| Professional Check | As needed | Annually |

| Replacement | Max 8 years | Max 8 years |

By following these schedules, I keep my fire safety equipment reliable and ready for emergencies. Regular maintenance gives me peace of mind, whether I am at home or at work.

Common Issues with Rubber Fire Hose Reel

Hose Degradation and Cracking

I often see hose degradation and cracking as a result of environmental exposure. Sunlight and ozone can break down the rubber over time, especially if the hose lacks protective layers. I notice that hoses stored outdoors without UV protection become stiff and brittle. High temperatures also cause the rubber to dry out, harden, or even crack when I flex the hose. Abrasion is another problem. When I drag the hose across rough surfaces, the outer layer wears down. This makes the hose more likely to leak or burst under pressure. I always check for these signs during my inspections and try to store my hose away from direct sunlight and heat sources.

Mold, Mildew, and Bacteria Risks

Moisture trapped inside the hose or reel can lead to mold, mildew, and bacteria growth. I have learned that storing a wet hose in a closed cabinet or reel creates the perfect environment for these problems. Mold and mildew not only smell bad but can also weaken the hose material. I always dry my hose thoroughly before storage. If I notice any musty odor or discoloration, I clean the hose with mild soap and water. Regular cleaning and proper drying help me prevent these health and safety risks.

Reel Mechanism Problems

Reel mechanisms can develop issues over time, especially if I do not maintain them. Corrosion is the most common problem I encounter. I often find pitting marks or seized parts on the couplings and floating flanges. Corrosion can prevent the reel from rotating smoothly and may even cause fittings to fail during pressure tests. I pay close attention to these areas during inspections. Using brass fittings instead of aluminum helps reduce corrosion risks. I also make sure everyone who uses the reel understands the importance of checking for corrosion and keeping the mechanism clean and lubricated.

Tip: I include a detailed check for corrosion in my regular maintenance routine to keep my fire hose reel reliable and safe.

Tips for Maintaining Rubber Fire Hose Reel

Proper Storage Practices

I always follow best practices when storing my Rubber Fire Hose Reel. Fire safety organizations recommend several steps to extend the lifespan of rubber hoses:

- Store hoses indoors whenever possible to protect them from sunlight and extreme temperatures.

- If I must store hoses outdoors, I choose shaded, dry areas and use protective covers.

- I avoid tight coils and instead use loose, even loops or a hose reel to prevent kinks.

- I keep hoses off the ground by using wall mounts, hangers, or cabinets.

- I make sure hoses stay away from sharp objects, oils, chemicals, and machinery.

- I clean hoses with mild detergent and dry them completely before storage.

- I inspect hoses often for cracks, leaks, and damaged fittings.

- I rotate hoses in storage to distribute wear evenly.

- I never store hoses in walkways or high-traffic areas.

These habits help me maintain hose flexibility and prevent damage.

Using Protective Covers

Protective covers play a key role in keeping my fire hose reel in top condition. I rely on covers to shield the hose from UV rays, rain, and abrasion. The table below shows how covers help:

| Protective Feature | Description and Effect |

|---|---|

| UV Protection | Stops cracking and fading from sunlight exposure. |

| Weather Resistance | Guards against rain, moisture, ozone, and chemicals, reducing hose degradation. |

| Abrasion Resistance | Prevents scratches and damage from rough handling. |

| Durability and Lifespan | With covers, hoses can last up to 10 years, staying flexible and strong. |

I always use a cover if my Rubber Fire Hose Reel is exposed to the elements.

Quick Troubleshooting Steps

When I face issues with my fire hose reel, I follow these steps to fix them quickly:

- I identify the problem, such as leaks or nozzle issues.

- I remove the nozzle and drain any water.

- I clean the nozzle with a mild cleaning agent, working it into the threads and seals.

- I flush out the cleaning agent thoroughly.

- I wipe away any extra lubricant from the internal parts.

- I disassemble the nozzle with simple tools to access the O-ring.

- I clean and re-lubricate the O-ring with plumber’s grease.

- I reassemble the nozzle, making sure not to over-lubricate.

- I test the nozzle to confirm it works properly and does not leak.

These steps help me keep my equipment reliable and ready for emergencies.

Rubber Fire Hose Reel Pros and Cons

Advantages for Home and Industrial Use

I have found that rubber fire hose reels offer several key benefits for both home and industrial settings. Their design makes them easy to use and maintain, which saves me time and effort. Here are some advantages I have experienced:

- Fixed hose reels keep hoses organized and prevent damage, which improves operational efficiency.

- Quick deployment and retraction help me respond faster during emergencies and reduce workplace hazards.

- The robust construction stands up to harsh environments, including exposure to chemicals and mechanical stress.

- Permanently mounted reels deliver consistent and reliable performance, which is essential for uninterrupted operations.

- Rubber hoses like Angus Fire Duraline and Snap-tite Hose HFX resist kinks, abrasions, and chemicals. They also have UV protection, so they last longer outdoors.

- The smooth interior design ensures maximum water flow, which is critical for high-pressure use.

- I appreciate that rubber-coated hoses require simple maintenance. I can usually clean them by wiping them down, unlike other hose types that need more thorough cleaning.

Note: Many manufacturers now offer features like automatic retraction and adjustable flow control, making these reels even more convenient for industrial users.

Disadvantages to Consider

While I rely on my rubber fire hose reel for many situations, I remain aware of some important limitations:

- I never use a fire hose reel on fires involving live electrical equipment because water can cause electrical hazards.

- These reels are not suitable for burning liquids like oil, since water can spread the fire.

- The continuous, large volume of water can be hard to control, especially for someone without training.

- If I do not maintain the hose properly, stagnant water inside can promote the growth of Legionella bacteria, which poses a health risk.

| Limitation | Why It Matters |

|---|---|

| Not for electrical fires | Water conducts electricity, increasing danger |

| Not for oil or liquid fires | Water can spread flammable liquids |

| Hard to control for beginners | May lead to ineffective firefighting |

| Risk of bacteria if not maintained | Health hazard from stagnant water |

By understanding both the strengths and limitations, I can use my rubber fire hose reel safely and effectively in any environment.

I find that a Rubber Fire Hose Reel remains reliable with simple, regular care. My routine includes these steps:

- I inspect and clean the hose to prevent wear.

- I store it away from sunlight and extreme temperatures.

- I replace worn parts before failure.

Consistent maintenance ensures long service life and dependable performance.

FAQ

How often should I replace my rubber fire hose reel?

I replace my rubber fire hose reel every 8 years or sooner if I see cracks, leaks, or other damage.

Tip: Regular inspections help me spot problems early.

Can I use any lubricant on the reel mechanism?

I always use lubricants recommended by the manufacturer. Using the wrong type can damage the reel or attract dirt.

- I check the manual for approved products.

What should I do if I find mold on my hose?

I clean the hose with mild soap and water, then dry it completely before storage.

Mold can weaken the hose, so I act quickly.

Post time: Aug-20-2025